Rubber Gate Seals

Key Features

- High quality materials

- High tensile strength properties

- Excellent tear resistance

- Good abrasion resistance

- Resistant against weathering deterioration

- Maintains flexibility even in sub-zero temperatures

- Wide variety of seal configurations & sizes available

- PTFE coating available

Product Description

Here at The Rubber Company we manufacture a wide variety of rubber gate seals to suit any application and environment. We produce our gate and dam seals from high quality rubber compounds in order to preserve the service life of the seal. We can also offer a large selection of standard profiles, which have been specifically designed to suit almost all applications. Alternatively, we can manufacture a bespoke gate seal to your exact specifications. This ensures that you can always get the best seal to suit your unique requirements.

Our rubber gate seals provide exceptional mechanical properties as well as good weathering and water resistance properties. The entire gate seal range features a high tensile strength as standard. Our gate seals also feature excellent abrasion and tear resistant properties. These properties are crucial as it enables the seal to withstand frequent use, while also maintaining sealing properties.

We supply rubber gate seals for use in; dam & canal gates, radial, stop log, sluice, penstock and vertical gate applications. The different seal designs have been specifically developed in order to suit different seal types and installations. We have a comprehensive gate seal brochure that lists the common gate seal types, as well as where you would use them and how they work. Don’t hesitate to get in contact with us if you are unsure which particular gate seal best suits your application. Our friendly and informative staff are always on hand to assist you however possible.

Different Seal Formats

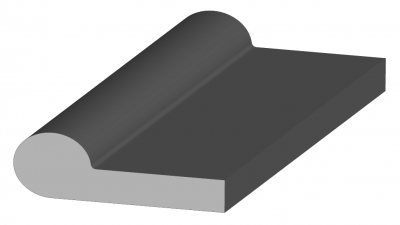

P Gate Seal

Our P seals or “music note seals” as they are also known, are available in two different formats. Depending on the load deflection criteria we may suggest either a solid or hollow bulb. The hollow bulb format is more suitable for use in low hydrostatic pressures. While the solid bulb format is less prone to compression.

When under pressure, either the bulb or stem can create a seal. Bulb deflection is appropriate for seals which are in high compression load applications. Whereas, stem deflection is more appropriate for use in; low compression loads, sealing irregular surfaces and large tolerances in the gate dimensions.

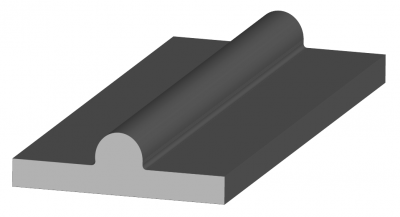

Double P Gate Seal

Our double P gate seals provide many of the same sealing properties found in our standard P gate seals. The main difference between the two, is that our double p seals enable you to seal against two surfaces using a single profile. The bulbs can compress under pressure in order to create a watertight seal.

Double P gate seals typically secured and bolted through the stem to provide bulb deflection. These seals are typically installed to a plate and then pressed against a sealing face. This ensures that the profile provides consistent sealing capabilities regardless of water pressure.

Hump Gate Seal

We can manufacture our hump gate seals in two standard formats. Either with a single or double hump depending on the application. Hump seals are generally used for sealing the top edge of submerged vertucal-lift gates. Our hump seal are typically bolted either side of the hump or the flat stem section of the profile. The hump section is then pressed against the sealing surface.

The flexibility of our hump profiles enables them to compress slightly when pressed against the sealing surface. This ensures that the profile is able to form a watertight seal regardless of the water flow and pressure.

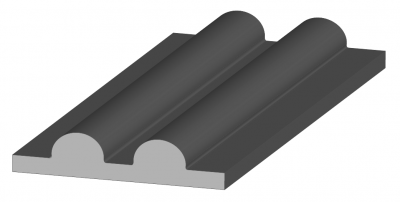

Double Hump Gate Seal

Similar to our hump seal profiles our double hump seal profiles create a seal using compression under pressure. Our double hump seals are often commonly used on tidal river gates. The dual humps can protect from water either side of the channel, similar to our double P seals.

Omega Gate Seal

Our omega gate seals are often used to create an internal seal between two surfaces on underwater tunnels. These seals generally perform as a membrane as they are exposed to three dimensional movements between the tunnel sections. Omega seals can also be reinforced with fabric in order to enhance the seal with additional mechanical properties. We can increase or decrease the number of fabric layers in order to suit the maximum hydrostatic pressure and required safety factor.

We can also manufacture our omega gate seals with a series of small ridges on the sealing face. This will ensure that the profile is able to create a watertight seal under a variety of pressures.

Lip Gate Seal

We can manufacture lip gate seals in order to suit a variety of lip angles and sizes. The design of our lip seals lends the profiles towards being naturally flexible. This enables them to be used for movement in one plane e.g. radial or vertical lift gates. Lip gate seals generally create watertight seals though water pressure, which presses the sealing lip against the sealing face.

Lip gate seals are typically bolted to a solid structure that sits above the sealing surface. This enables the angled section of the seal to sit against the sealing surface, which can then bend to create a watertight seal when required.

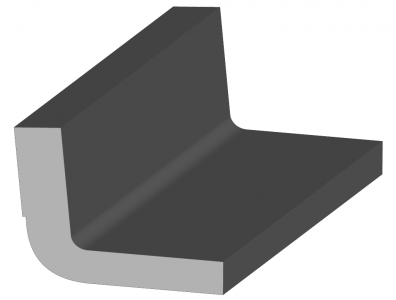

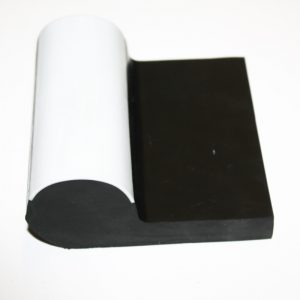

Flat Gate Seal

We can manufactured our flat gate seals in three sealing face formats; flat, chamfered or radiused. The chamfered and radiused formats decrease the surface area that will come into contact with the sealing surface. This creates more room for the the rubber to displace while under pressure.

Flat gate seals are typically installed as bottom seals, which mean that they protrude below the sealing structure. Flat bottom seals on high head gates should project no more than the deflection required to seal e.g. 3-5mm.

PTFE Coating

If required we can coat many of our rubber gate seals with a high quality PTFE coating. A key advantage of PTFE coating is that it significantly reduces surface friction without the need for lubricant. On average the coefficient of friction can be reduced by over 70%, regardless of the base rubber compound.

The superior friction characteristics serve to not only increase functionality, but also to extend the service life of the seal. The PTFE coating can help to prevent the seals from sticking, twisting and even tearing while in use. Aside from the obvious practical advantages, PTFE coating can also be used to add colour to the sealing face of the gate seal. This helps to increase visibility of seal and makes it easier to identify any surface damage.

Specifications

| Application: | A variety of heavy duty watertight sealing applications |

| Product: | Gate Seal Profiles |

| Hardness (Shore A): | 40° - 75° |

| Material: | Natural Rubber / EPDM / Neoprene |

Potential Applications

- Dry-dock seals

- Lock seals

- Gate Seals

- Hopper barge seals

- Water works

- Flood protection