When it comes to ensuring the highest standards of food safety, every detail matters. From manufacturing processes to the materials used, it’s crucial to prioritise quality at every step. At The Rubber Company, we understand the importance of reliable food grade gaskets which is why ours fully conform to FDA standards for use in food and beverage applications. Our team of experts, with over 100 years of experience, can work directly with you to meet your unique requirements. Our bespoke manufacturing capabilities, facilitated by the latest CNC machinery, allows us to create custom gaskets using a wide range of solid and sponge rubber compounds.

The food and beverage industry demands utmost compliance with food safety regulations. To address this, our food contact gaskets are meticulously designed to conform to the rigorous standards set by the FDA. By utilising premium solid and sponge rubber compounds, we can manufacture gaskets that provide a safe and hygienic barrier between various components in food processing and packaging equipment.

Our food quality gaskets are designed to excel in various temperature conditions, offering a wide operating range. In demanding food processing environments, temperature variations can be a challenge. However, our food quality gaskets are engineered to excel under high temperatures. While specific temperature limits may vary depending on the material, all our compounds are carefully selected and designed to ensure consistent performance even in extreme heat. This means you can rely on our gaskets to maintain their integrity and functionality, even in the most demanding hot conditions.

Ensuring the safety and well-being of consumers is paramount. That’s why our food contact gaskets are manufactured from non-toxic and non-allergenic rubber compounds. These materials have been specifically chosen to meet strict regulatory requirements and provide a hygienic seal between food processing and packaging equipment. With our gaskets, you can be confident that there will be no risk of harmful substances leaking into your products, maintaining the highest standards of food safety.

The presence of moulds and water can be detrimental to food processing equipment, leading to contamination and compromised performance. Our food quality gaskets are designed to combat these issues effectively. With excellent mould resistance, our gaskets help prevent the growth of organic matter on their surface, reducing the risk of contamination and prolonging their lifespan. Additionally, the water resistance properties of our gaskets ensure that they maintain their integrity and functionality, even in moist or humid environments. Maintaining the natural taste and aroma of food and beverages is essential for customer satisfaction. Our food grade rubber gaskets are specifically formulated to be tasteless and odourless. This means that when in contact with your products, our gaskets will not impart any unwanted flavours or aromas, preserving the true quality and characteristics of your food and beverages.

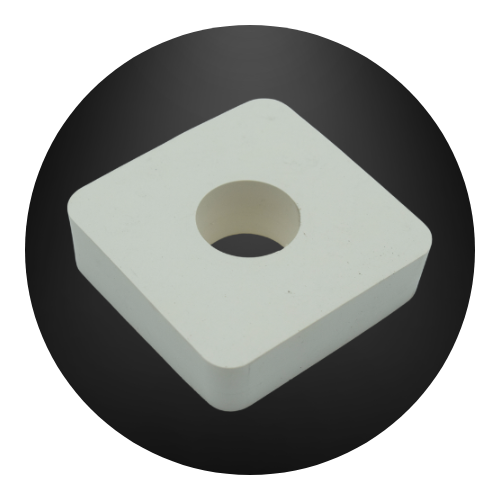

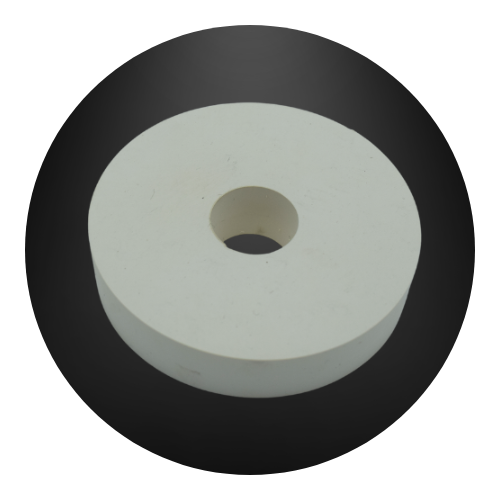

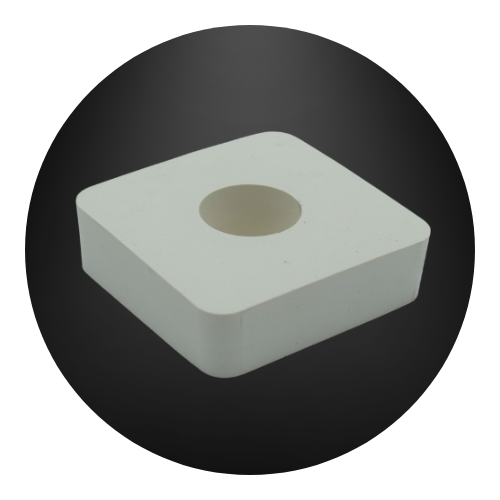

At The Rubber Company, we have perfected our manufacturing process for food quality gaskets. By utilising sheets or rolls of rubber, we can create large, uniform gaskets without the need for bonding or joins. Our extensive selection of cutting and manufacturing machinery further enhances our capabilities, enabling us to produce gaskets of varying complexities with tight tolerances.

Our diverse range of cutting and manufacturing CNC machinery provides us with the flexibility to tackle projects of different sizes and complexities. Whether you require simple gaskets or intricate designs, our state-of-the-art equipment allows us to deliver precision-engineered solutions that meet your specifications.

When it comes to food quality gaskets, there is a wide range of rubber compounds available, each offering distinct properties. Selecting the correct material for your specific application is crucial. Not only does it ensure that your gaskets are suitable for use, but it also prevents unnecessary expenditure on properties that may not be required for your particular application. To assist you in making an informed decision, we have compiled a list of our most popular food contact gasket materials below.

EPDM Rubber

Aside from being food contact safe, our EPDM food grade gaskets also provide excellent weathering and ozone resistance. This enables them to function in both interior and exterior applications without affecting the service life of the material. For applications that require it, EPDM gaskets also feature good ageing and chemical resistance.

Neoprene® Rubber

Neoprene® food contact gaskets combine food safe properties with good resistance against oils, fats as well as grease deterioration. This enables them to be used in a number of highly specialised applications. Neoprene® typically offers impression mechanical properties such as high tensile strength and tear resistance properties. This enables the gaskets to provide consistent performance, even in frequent use applications.

Silicone Rubber

Silicone rubber is perhaps the most common material for manufacturing food contact gaskets. These gaskets combine good chemical resistance with the excellent high temperature resistance. Silicone rubber also features good mechanical properties as well as good resistance against weathering, UV and ozone deterioration. This ensures that our food grade silicone gaskets are suitable for a wide variety of applications and environments.

Natural Rubber

Natural rubber gaskets are well known for offering superior flexibility and elongation properties when compared with other rubber compounds. They can also provide high tensile strength, tear and abrasion resistance. This combination of physical properties makes natural rubber food grade gaskets suitable for use in high wear and compression applications. Natural rubber gaskets also feature good resistance against alcohol, ketones and organic acids deterioration.

Nitrile Rubber

Our Nitrile food grade gaskets are available in either blue or white colours depending on the application. This is a premium quality material, which is manufactured to provide a high service life in abrasive applications. It features good oil, fat and grease resistance as standard as well as wide operating temperature range.

Viton

Our Viton® food contact rubber is a high quality, specialist material. We produce this particular grade using an FKM A quality compound. It is ideal for use in food and beverage processing applications due to the unique combination of properties it provides. Our food grade Viton® sheeting features top in its class resistance against animal fats as well as food related oils. It is also able to maintain this resistance and physical properties across a broad temperature range from -30°C up to +275°C.