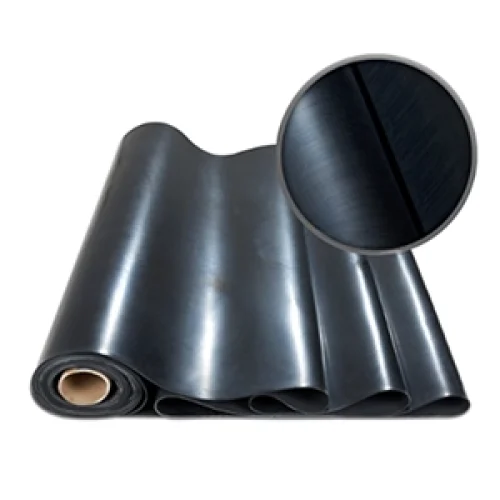

Rubber Sheeting

When it comes to materials that can withstand the toughest environments, few can match the performance of silicone rubber. Known for its flexibility, durability, and heat resistance, silicone rubber has become a go-to material across a wide range of industries – from automotive and electronics to medical and food processing.

What Makes Silicone Rubber So Special?

Silicone rubber is made from a unique polymer that combines silicon, oxygen, carbon, and hydrogen. This special chemistry gives it remarkable stability and the ability to perform under extreme conditions – from sub-zero temperatures to scorching heat. Unlike many other materials, silicone rubber won’t crack, melt, or lose its properties, even after years of use.

Beyond temperature resistance, silicone rubber is also non-reactive, weatherproof, and long-lasting, making it ideal for seals, gaskets, tubing, and protective components. It’s available in a variety of forms – solid, liquid, and foam – allowing manufacturers to shape it precisely for any application. Plus, it can be dyed to virtually any colour, offering both functional versatility and aesthetic flexibility to suit a wide range of product designs and branding needs.

Key Benefits of Silicone Rubber

- High temperature resistance: Performs reliably between -60°C and +250°C

- Excellent flexibility and resilience: Maintains elasticity over time

- Superior electrical insulation: Perfect for sensitive electronic applications

- Non-toxic and biocompatible: Safe for food and medical use

- UV, ozone, and ageing resistance: Built to last, indoors or outdoors

Thanks to these advantages, silicone rubber is trusted wherever reliability and safety are top priorities.

Specialised Silicone for Every Industry

Not all silicone rubber is the same. At The Rubber Company, we offer a range of specialised silicone materials designed for specific applications:

- Rail and mass transit: Silicone compliant with EN-45545-2 for fire safety.

- Metal detectable silicone: Ideal for food and pharmaceutical industries, helping to reduce contamination risks.

- Silicone glass-coated cloth: Used for insulation and heat shielding in demanding environments.

- FDA-approved silicone: Certified for direct food contact (FDA 21 CFR No: 177–2600 / EU1935/2004).

A Material You Can Trust

Whether you’re developing high-performance equipment, designing safe food-grade products, or engineering reliable seals for transport systems, silicone rubber delivers the strength, flexibility, and confidence you need.

At The Rubber Company, we’re proud to supply quality silicone products that meet the highest standards – helping our customers create safer, more durable, and more innovative solutions every day.