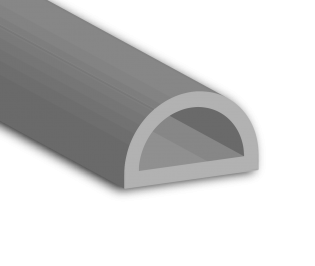

Natural Rubber D Profiles

Key Features

- High-quality natural rubber

- Highly durable

- Excellent friction resistance

- High tensile strength

- Good tear resistance

- Non-reactive

- Available in non-marking colours

Product Description

Our range of natural rubber D profiles are highly durable and dependable. We manufacture them from a high-quality natural rubber / SBR compound to provide superior impact absorption properties. We also supply a wide range of shapes and sizes to suit any purpose.

These natural rubber fenders are ideal for protecting against both small and large impacts. Each profile is designed and manufactured to provide excellent friction resistance and high tensile strength. This feature enables them to be in constant use without fear or deterioration.

Our natural rubber D profiles are the perfect solution for anyone who is looking for complete protection. Each profile features a shore (A) hardness of 72°, which means it is a relatively firm product. Despite being firm however, the extrusions can compress under pressure which enables them to absorb heavier impacts while also transferring the kinetic energy away from the property or object. This gives you complete peace of mind knowing that you are protected from any impact, and also that the rubber D profile isn’t going to warp or deteriorate after use. If you are unable to find the exact product you want, please contact us about a custom profile.

Specifications

| Application: | Marinas, Jetties, Sea Vessels, Loading Bays, Parking Areas, Impact Protection |

| Product: | Natural Rubber D Profiles |

| Hardness (Shore A): | 72° |

| Material: | Natural Rubber (NR/SBR) |

| Colour: | Black as standard but non-marking colours available |

Potential Applications

- Boat fenderings

- Marina and jetty fenders

- Lorry loading bays

- Parking protection

- Wall protection

- Warehouse packing lines

- Interior and exterior applications

Technical Data

| Properties | Test Method | Values | |

|---|---|---|---|

| Density | DIN 53505 | 1200 kg/m3 | |

| Tensile Strength | DIN 53504 | ≥16 MPa | |

| Elongation at Break | DIN 53504 | ≥350% | |

| Tear Resistance | DIN 53507 | ≥80 N/cm | |

| Abrasion Resistance | DIN 53516 | ≤100mm3 | |

| Compression Set (24hrs @ 70°C) | DIN 53517 | ≤40% | |

| Ozone Resistance | ISO 143/1 | No cracking visible | |

| Air Ageing | |||

| Change in Hardness | DIN 53505 | ≤5 | |

| Change in Tensile Strength | DIN 53504 | ≥80% | |

| Change in Elongation at Break | DIN 53504 | ≥80% |