D Fenders

Key Features

- Specifically designed for impact absorption

- Ideal for small and large scale installations

- Highly durable tough rubber bumper

- Good resistance to UV and ozone

- Can be supplied in long lengths

- Easy to install

- Can be supplied in non-marking colours

Product Description

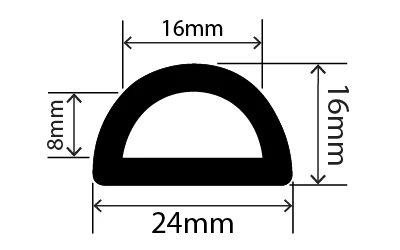

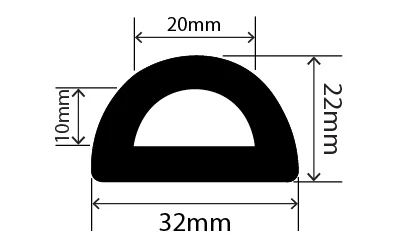

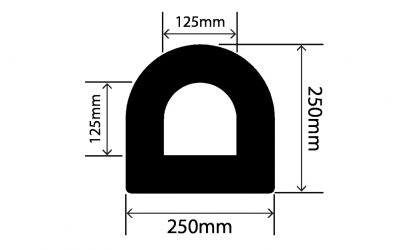

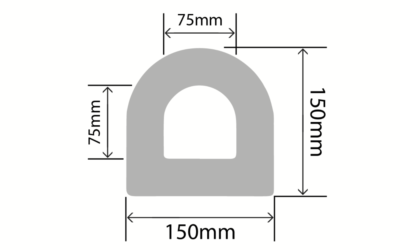

The Rubber Company manufacture and supply a wide range of high quality, rubber D fenders. Our fenders are available in many different shapes and sizes in order to suit a variety of requirements. We can produce both hollow and solid fenders in sizes ranging from 20mm up to 500mm to ensure you get the perfect product for your unique application.

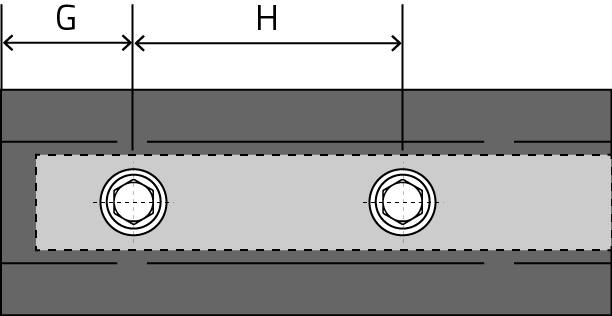

Rubber D fenders have become increasingly popular due to the high versatility and excellent protection that they offer. The fenders are designed to be securely attached to many surface types using bolts. Many of the D fenders we offer are available pre-drilled, which ensures that the bolts are evenly spaced out and also greatly reduces installation times. We also offer the option of providing your fenders pre-curved, chamfered and cut to specific lengths. This ensures that they maintain a perfect fit and allows you install the product as soon as it arrives.

Our extruded D fenders are made from either a natural rubber/SBR or EPDM compound. Both of these compounds provide the fenders with superior physical properties and excellent UV and weathering resistance. Featuring a high tensile strength, our fenders can protect against a wide variety of impacts without warping or deteriorating.

Different Formats to Choose From

In order to ensure that you get the perfect product for your unique application we offer our D fenders in a choice of six different formats, with each offering their own strengths.

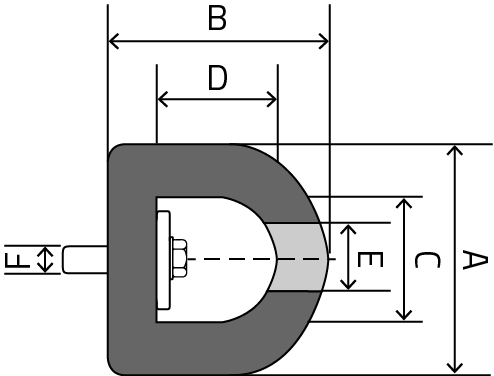

DD Fenders

These fenders get their name from the D shape of the fender and the D shape of the inner hole. DD type fenders are some of the most common format of fenders which are used on marines and jetties all over the world. These fenders are drilled straight down through the centre in order to bolt the fender to the desired surface.

DO Fenders

DO type fenders are similar in design to DD fenders however, these fenders feature a round shaped hole running through them. These particular fenders are drilled through the base, which enables you to bolt the fender into a channel. This makes them popular for use directly on sea vessels.

Delta Fenders

Delta fenders are slightly more angular compared to the standard D fenders. This reduces the surface area which is in contact with the impacting object. Delta fenders are ideal for use on any type of vessel and are also easy to mount.

Winged Fenders

Winged D type fenders are typically smaller in design than the other D fenders which make them perfect for use on small ports. Their unique design is excellent at protecting ships which berth abnormally.

M Series Fenders

These fenders are designed for rigid mounting as a continuous strip on quays, jetties as well as pontoons. You can also install these fenders as belting on tugboats and work-boats.

Solid Fenders

As the name suggests, our solid D fenders provide a solid barrier to protect you from impacts. However, they offer reduced compression rates compared with the hollow alternatives. This makes them better suited towards larger sea vessels or applications which come under heavy impact or pressure.

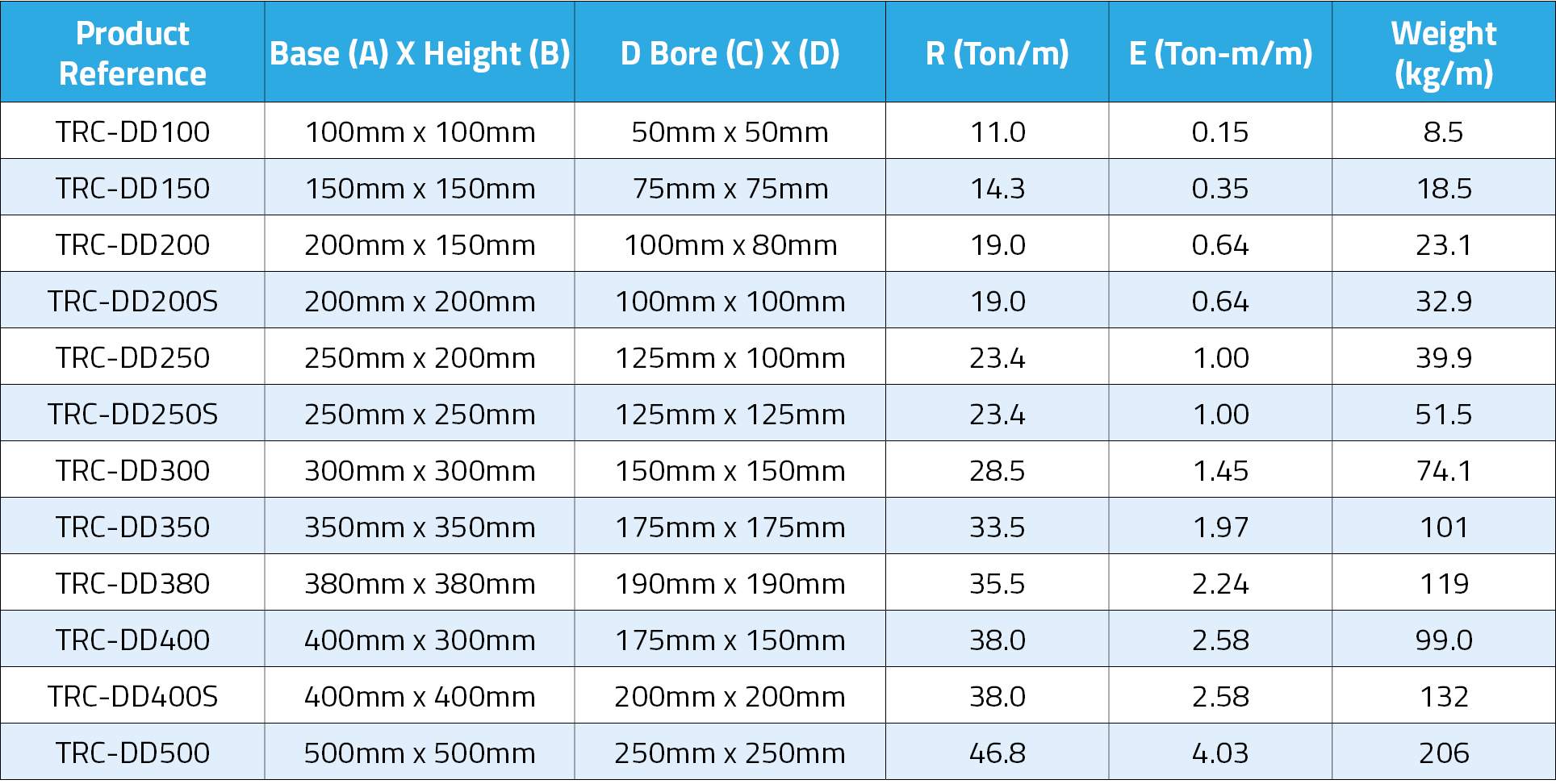

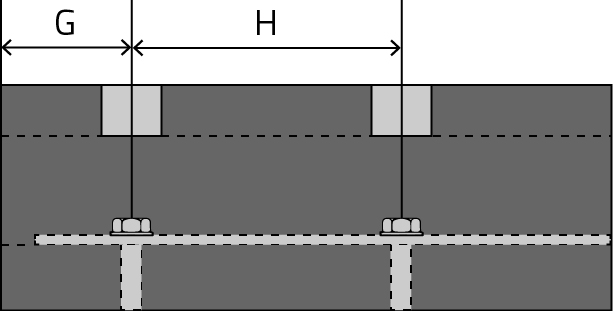

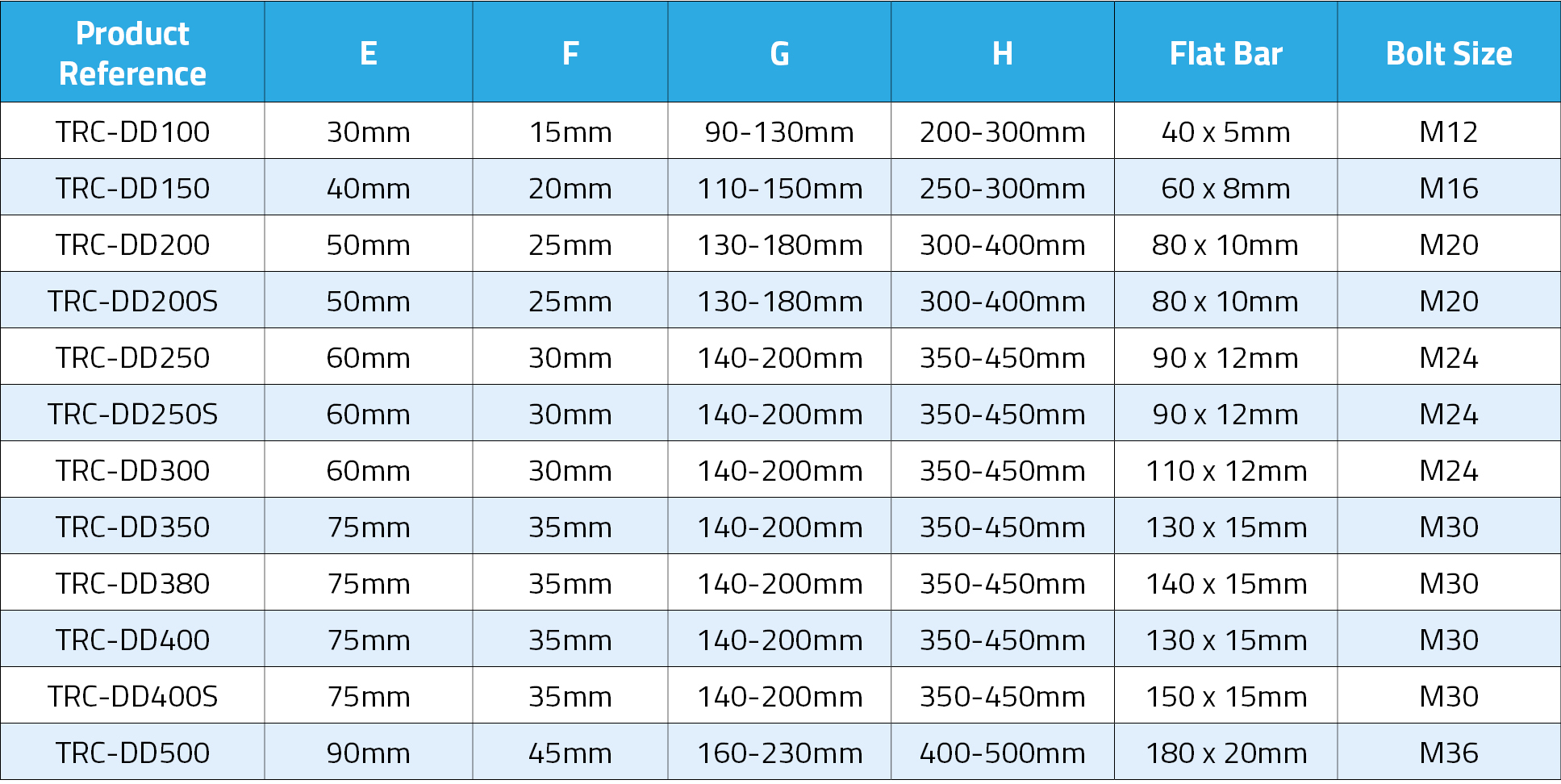

DD Fender Specifications

Drilling Holes and Installation

Specifications

| Application: | Impact protection in a variety of marine applications |

| Product: | Marine D Fenders |

| Hardness (Shore A): | 70° |

| Material: | Natural Rubber / SBR or EPDM |

| Colour: | Black / Non Marking Grey |

Potential Applications

- Protection for small and large sea craft

- Marinas and jetties

- Parking spaces

- Loading bays

- Warehouse production lines

- Any area that requires protection from impact

Do not hesitate to get in contact with us for more information regarding our full range of D fender manufacturing capabilities.