Silicone Rubber Inflatable Seals

Key Features

- High quality and durability

- Wide functioning temperature range

- Excellent shape memory

- Maintain seal in moving parts

- Able to seal when sealing gap may be uneven

- Quick to inflate and deflate

- Easy to install

- Range of colours available

Product Description

The Rubber Company manufacture and supply an extensive range of rubber inflatable seals for use in a wide variety of applications and environments. Our highly versatile seals are a high-quality product, which enables them to be used in specialised industries from the pharmaceutical to the nuclear sector.

We keep a large selection of our most popular inflatable seals in stock, as this enables us to offer faster delivery times to ensure that you get the product when you need it. We can also produce custom and bespoke profiles, designed and manufactured to meet your unique requirements and in almost any colour, which enables them to blend in or stand out from their surroundings as required.

Our rubber inflatable seals are the ideal product for a variety of applications, where sealing two surfaces that move in relationship to each other is required. By introducing a medium such as air or fluid, a rubber seal will begin to expand at a specified rate until a determined size of inflation is achieved.

We can also manufacture our inflatable seals from an FDA approved silicone rubber, which is available in blue, white and red colours. Other material compounds are available upon request.

Seal Configurations

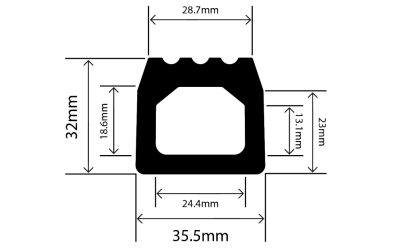

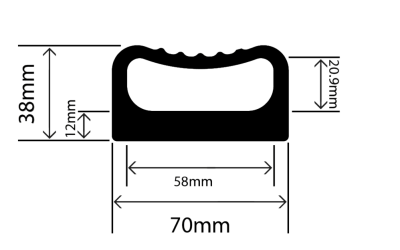

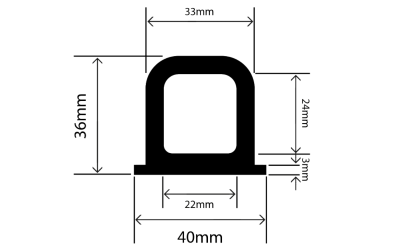

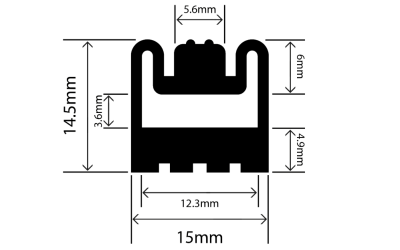

There is a choice of six different seal configurations. This enables us to provide a seal which is tailored to your unique application. It is important to select the correct configuration in order to achieve maximum sealing capabilities.

Radial In

The Radial In configuration is ideal for use in clamping applications. The seal is typically flat on one side which enables you install it on a variety of surfaces. Once inflated the seal pushes upwards to provide a tight seal on any object it comes into contact with. Our customers also use this configuration on maintenance shafts and valve seals for this reason.

Radial Out

Inflatable seals which use this configuration inflate outwards away from the centre of the seal. This provides equal sealing on both sides of the seal, making it perfect for use in applications which don’t provide adequate surface to attach the seal to. You can clamp these types of seals in place or insert into a groove. Airlock doors often use this type of seal.

Axial

These seals are designed to inflate in a direction 90° away from the radius of the seal. This makes it ideal at providing sealing around corners or curved surfaces as the seal always inflates in the same direction. Axial seals are popular in door and hatch seal applications.

Straight Length

These inflatable seals are blocked at both ends which enable them to provide sealing in strips. They can always be manufactured in straight lengths if the application requires it. This makes them ideal for use in production lines as clamps or as a watertight seal under large sliding doors.

Rectangle with Moulded Corners

The corners on these seals are often pre-moulded which ensures that the seal is able to provide a tight fit around even the tightest corners. Our customers commonly use these particular seals on sliding doors.

Goal-Post Shaped

These inflatable seals combine straight length seals with the moulded corner seals in order to create a U-shaped seal which expands axially. This ensures that the same level of sealing is maintained on each side of the object you are using it on. These particular seals are also used on sliding doors.

Specifications

| Application: | Door seals, hatch seals, waste incinerators, mineral processing, chemical processing, rail and tramways, pharmaceutical, and food industries |

| Product: | Inflatable Seal Profiles |

| Hardness (Shore A): | 60º |

| Material: | Silicone |

| Colour: | Any |

Potential Applications

- Door seals

- Hatch seals

- Waste incinerators

- Iron and steelworks

- Mineral processing

- Sand filling systems

- Chemical processing

- Rail and tramways

- Pharmaceutical and food industries

Technical Data

| Properties | Values | ||

|---|---|---|---|

| Compound | Silicone | ||

| Density [Specific Gravity] | 1.16 g/cm2 | ||

| Tensile Strength | 10 MPa | ||

| Elongation at Break | 450% | ||

| Tear Strength | 25 Kn/M | ||

| Minimum Temperature | -70ºC | ||

| Maximum Temperature | +200ºC | ||

| Compression Set | 35% |