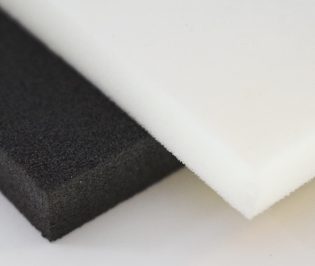

Plastazote Foam

Key Features

- Genuine plastazote foam

- Highly durable

- Recovers from repeated impacts

- Excellent chemical resistance to most oils, solvents, acids & alkalis

- Non-toxic, odourless, buoyant & non-absorbent

- Very good thermal insulator

- Weatherproof with good ultraviolet stability

- Easily shaped, cut & bonded to other materials

Product Description

Genuine Plastazote is a material with almost unmatched durability and versatility in the foam and sponge market. The material is a closed cell, cross-linked polyethylene foam which is incredibly lightweight. It is also absent from any chemical agents which enable you to use this material in highly sensitive environments.

One of the key features of Plastazote is the materials ability to recover from frequent and heavy impacts. This ensures that the material is not only dependable but also great value for money. It also offers excellent resistant to a wide variety of chemicals, solvents, acids, alkalis as well as most oils. These features enable our customers to use it in a range of industries and applications. The materials excellent thermal insulation properties make it ideal for use in automotive and construction industries. Plastazote is also lightweight and free from any chemical agents which make it popular in both the science and medial industries.

We are able to supply genuine Plastazote in a variety of formats depending on your unique specifications. We often get requests for Plastazote in: sheets, rolls, strips, gaskets as well as seals. You also have the option of a plain or adhesive backed finish which provides a fast, simple installation solution. We offer Plastazote in four densities of 18, 24, 33 and 45kg/m3. Each density has its own values so be sure to check our material spec sheet in order to ensure you get the right density for your specific requirements.

Specifications

| Application: | Delicate & high impact protection, thermal insulation, gaskets & seals |

| Product: | Plastazote Foam |

| Hardness (OO): | 50° - 63° |

| Material: | Polyethylene |

| Colour: | Black, White, Blue, Red, Yellow, Green available as standard. Other colours available as a special order. |

Potential Applications

- Delicate object storage & protection

- Thermal insulation

- Backing & support panels

- Drawer & box liners

- Customised packaging

- Picture framing

- Full rolls, strip cut lengths, gaskets & adhesive tapes.

Material Conversion Possibilities

Here at The Rubber Company we can utilise a variety of sponge rubber conversion tools and techniques. This enables us to cut, shape, drill, join and laminate our materials to match your exact requirements. Rubber sponge materials are manufactured in large blocks, so it is necessary to convert these blocks into usable end products. Our dedicated team can work directly with you every step of the way. This ensures that we use the best methods in order to achieve your desired shape and finish.

Technical Data

| Properties | Values 18 kg/m3 | Values 24 kg/m3 | Values 33 kg/m3 |

|---|---|---|---|

| Hardness (Shore OO) | 50° | 50° | 58° |

| Cell Size | 0.8mm | 0.3mm | 0.4mm |

| Tensile Strength | 299 kPA | 328 kPa | 419 kPa |

| Elongation at Break | 110% | 123% | 149% |

| Tear Resistance | 1317 N/m | 1254 N/m | 1888 N/m |

| Compression Set (25%, 1/2 hr) | 11% | 11% | 9% |

| Compression Set (25%, 24 hrs) | 4% | 4% | 4% |

| Compression (25%) | 50 kPa | 52 kPa | 66 kPa |

| Compression (50%) | 112 kPa | 116 kPa | 133 kPa |

| Thermal Conductivity (10°C) | 0.039 W/m.K | 0.036 W/m.K | 0.039 W/m.K |

| Flammability | Pass (13mm and thicker) | Pass (13mm and thicker) | Pass (9mm and thicker) |

| Minimum Temperature | -70°C | -70°C | -70°C |

| Maximum Temperature | +105°C | +105°C | +105°C |

| Standard Sheet Size | 2m x 1m | 2m x 1m | 2m x 1m |

| Thickness | 1mm - 25mm | 1mm - 25mm | 1mm - 25mm |