Evazote Foam

Key Features

- Highly durable material

- Recovers from repeated impacts

- Excellent chemical resistance to most oils, solvents, acids & alkalis

- Easily shaped, cut & bonded to other materials

- Non-toxic, odourless, buoyant & non-absorbent

- Can be washed, disinfected & wiped clean

- Very good thermal insulator

- Weatherproof with good UV stability

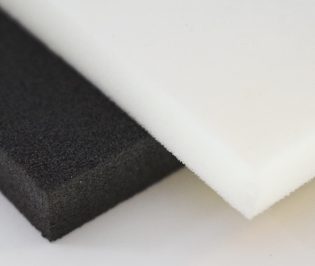

Product Description

Genuine Evazote foam offers superior softness, toughness and resilience compared to Plastazote. Evazote is a highly durable closed cell, cross-linked ethylene copolymer foam. This material is available in two main grades; EV and VA with the difference between the two being the proportional makeup of the ethylene vinyl acetate copolymer.

A key feature of Evazote is the materials excellent softness, which makes it perfect for use in physical contact applications such as sports and leisure. The superior softness gives the material a unique, high quality feel even in lower densities. Evazote is also tougher than Plastazote which grants the material with additional durability. This enables the material to absorb impact and pressure without tearing or deteriorating. Finally, Evazote offers excellent resistance to a variety of chemicals and environments. This makes the material perfect for use in harsh applications.

We are able to produce and supply Evazote in a variety of formats and grades to suit your unique requirements. Evazote is available in four densities as standard; 30, 35, 45 and 50kg/m3. This gives you complete control over the outcome of your product and ensures that it is tailored to suit you. We always recommend checking the spec sheet in order to ensure you choose the correct density. For applications which require it we can also produce Evazote in conductive grades, which make it perfect for us in specialised or scientific applications. We can also supply Evazote in a wide variety of attractive colours, to enable it to stand out or blend in depending on your preference.

If you are unsure which density or format is most appropriate for your application, please don’t hesitate to get in contact with us. We are always happy to help.

Evazote material is highly resilient which enable you to use it in a wide variety of applications. The superior toughness that this particular material offers make it resistant to abrasion deterioration. This enables the material to be in constant use without fear of warping or tearing. Evazote is also resistant to many of the most common oils and chemicals. It is also UV stable and resistant to salt damage which make it perfect for use in interior as well as exterior environments.

Evazote also features a wide functioning temperature range. The material is able to maintain its useful properties in temperatures as low as -70°C to as high as 100°C. This enables you to use this particular material in almost any environment with ease.

Evazote is available in two grades:

EV = ethylene vinyl acetate (higher VA content)

For example, the 50kg/m3 density of the EV grade equates to a Polymer – ethylene vinyl acetate level of 18%

VA = ethylene vinyl acetate (lower VA content)

For example, the 25kg/m3 density of the VA grade equates to a Polymer – ethylene vinyl acetate level of 9%

It is important to note however, that these properties are unique to the genuine Evazote foam material. Cheaper, imitation materials may look similar but simply can’t match genuine Evazote in terms of quality. We only supply the highest quality materials possible to ensure you get the best product possible.

Specifications

| Application: | Sports, Leisure, Construction industries, Expansion joints, Boat fenders, Industrial gaskets |

| Product: | Genuine Evazote Foam |

| Hardness (OO): | 40° - 57° |

| Resistant To: | Water, Chemicals, Grease, Oils, Mildew, Rot, Bacteria, Weathering, Tearing |

| Material: | Polyethylene |

| Colour: | Black, White, Blue, Red, Yellow, Green available as standard. Other colours available as a special order. |

Potential Applications

- Sports & leisure

- Footwear

- Construction industries

- Beauty products & nail buffers

- Protective padding including knee pads

- Expansion joints

- Gym mats

- Boat fenders

- Industrial gaskets

Material Conversion Possibilities

Here at The Rubber Company we can utilise a variety of sponge rubber conversion tools and techniques. This enables us to cut, shape, drill, join and laminate our materials to match your exact requirements. Rubber sponge materials are manufactured in large blocks, so it is necessary to convert these blocks into usable end products. Our dedicated team can work directly with you every step of the way. This ensures that we use the best methods in order to achieve your desired shape and finish.

Technical Data

| Properties | Values | ||

|---|---|---|---|

| Standard Sheet Size: | 2m x 1m | ||

| Thickness: | 1mm - 25mm |