Coated Fabrics For Defence

Key Features

- Military-grade durability

- High-strength fibre options

- Advanced rubber & polymer coatings

- Wide substrate compatibility

- Custom-engineered solutions

- Precision coating & lamination

- Excellent environmental resistance

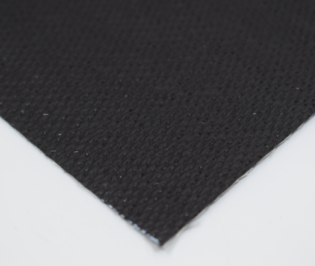

Military-Grade Textiles

At The Rubber Company, we specialise in high-performance military-grade textiles engineered for extreme environments. Our rubber coated fabrics and advanced coated materials are developed to meet the stringent requirements of global armed forces and law enforcement agencies. Designed for maximum protection and reliability, our textiles perform consistently in all climates and conditions.

Using a wide range of high-strength fibres – including Carbon, Aramid, Nylon, PTFE, Polyester, and S2 Glass – we supply premium coated fabrics to leading manufacturers of non-metallic armour and defence equipment.

Customised Coated Material Solutions

We work closely with clients to deliver custom coated material solutions that meet precise performance and safety requirements. Our extensive coating options include chloroprene, chlorosulfonated polyethylene (CSM), and polyurethanes, applied to high-performance substrates such as nylon, para-aramid, meta-aramid, Kevlar®, FR cotton, and Nomex.

Our materials serve a wide range of industries, including aerospace, automotive, healthcare, manufacturing, marine, outdoor recreation, defence, safety, rail, and mass transit.

Substrates, Coatings & Advanced Technology

With a wealth of expertise and a comprehensive selection of substrates, we align material properties precisely with each application. Our rubber, urethane, and polymer coatings are engineered to enhance durability, strength, and environmental resistance.

Through advanced coating, lamination, and hot-melt technologies, we produce textiles renowned for their reliability, longevity, and superior performance in demanding environments.

Defence & Safety Applications

Technical Data

| Property | Value | Capabilites | |

|---|---|---|---|

| Thickness Range | 0.1mm - 3.0mm (0.004" - 0.120") | Unvulcanised or vulcanised (uncured or cured) | |

| Width | Up to 2.1 (2100mm) | Knife over roller coating | |

| Knife over air coating | |||

| Dipped or impregnating | |||

| Wet frictioning | |||

| Laminating or doubling | |||

| Black or coloured coatings | |||

| BS-EN-ISO 9001 approved |