How Do We Test Our Entrance Matting Systems?

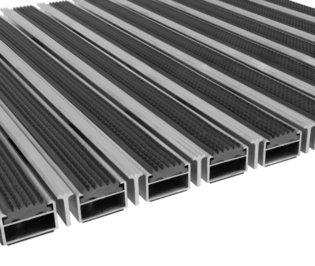

Key Features

- Standardisation of processes

- Reliability confirmed through tests

- Flammability Class: CFL-S1

- Safety and comfort of users

Quality Control

We consistently subject our produced Entrance Matting Systems to rigorous testing in both internal and external laboratories. This allows us to maintain unwavering quality control over our products.

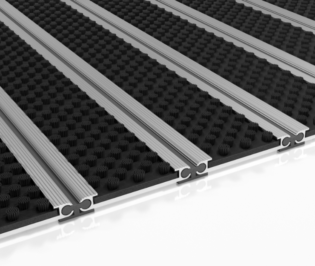

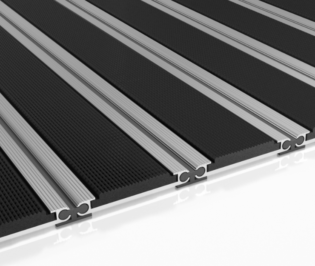

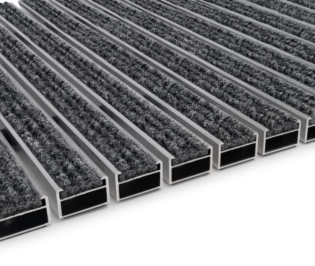

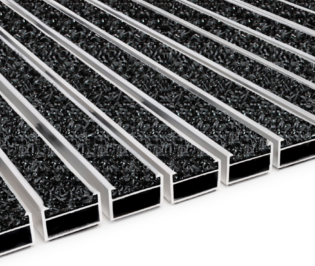

The majority of these systems are utilised in high-traffic establishments such as airports, shopping centres, and hotels. Consequently, their ability to withstand various weather conditions and heavy loads, including increased foot traffic, shopping carts, cleaning machinery, and luggage, is a critical attribute.

Standardisation of Processes

In order to instill confidence in our clients about the standardisation of our processes, we regularly undergo audits. Our receipt of the ISO-9001 certificate in 2015 serves as confirmation of our adherence to international standards throughout our production procedures. Our comprehensive quality control programs encompass various stages, such as initial quality control of raw materials, ongoing quality checks during the production process, as well as reliability and environmental testing. All aluminum wipers are subjected to stringent tests along the production line.

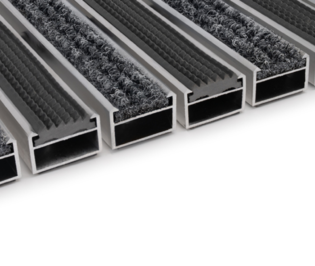

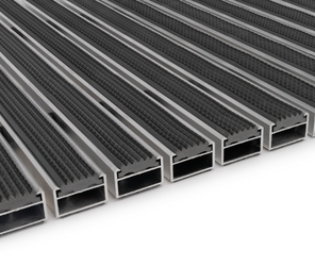

Reliability Confirmed Through Testing

Our rigorous testing procedures include assessing the load capacity and resilience to various weather conditions of our entrance matting systems. To evaluate the performance of the aluminium profiles, a static compression test was conducted using a testing machine at the Metal Testing Plant, an integral department of the Institute of Plastic Forming. Despite being put under a pressure of 3.9 kN (equivalent to 397.69 kg), all samples maintained their original height and shape, demonstrating exceptional durability and structural integrity.

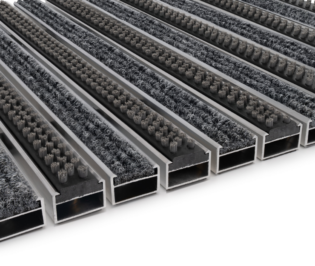

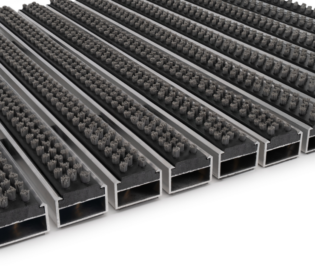

Comfort and Safety

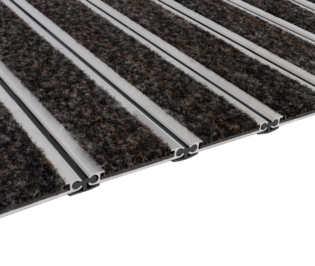

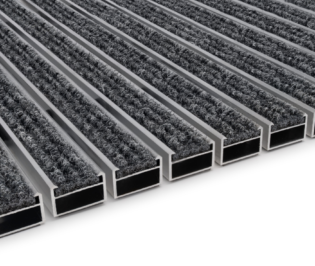

In addition, we ensure the safety and comfort of our products for users by:

- Reducing any uneven surfaces that may pose tripping hazards

- Eliminating gaps that could trap heels

- Conducting tests to evaluate water absorption levels and prevent slipping incidents

Furthermore, in 2016, our Entrance Matting Systems were certified for their anti-slip capabilities by the Institute of Ceramics and Building Materials (R11, R12, and R13).

Certificates and Approvals

Our products adhere to the necessary hygienic standards, as evidenced by the hygiene certificate issued by the National Institute of Hygiene.

We also have confirmation of the flammability class Cfl – s1.