PVC-Air Workplace Matting

Key Features

- Durable two-layer, tubular construction

- Made from non-porous PVC for superior performance

- Fatigue-reducing and insulating benefits

- Certified slip-resistant (DIN 51130: R11, ASTM 1677: 0.6/0.6)

- Exceptional drainage capabilities (DIN 51130: V10)

- Resistant to chemicals, oils, and acids

- Easy to install, clean, and maintain

Product Description

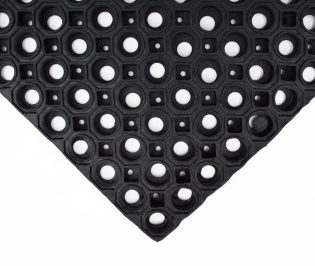

PVCAir is the ideal choice for high-performance, anti-slip workplace matting. Crafted with a non-porous, open-grid design, this mat resists fluid absorption and allows superior drainage, while an etched surface enhances traction for slip resistance. Designed to support employees working on their feet, PVCAir offers anti-fatigue benefits to reduce strain in workshop, factory, and industrial settings where liquid exposure and prolonged standing are concerns.

Thanks to its lightweight, tubular construction, PVCAir is simple to install, reposition, and clean, making it a convenient solution for improving workplace safety and comfort.

Installation Guide:

- Prepare:

Roll out your PVCAir matting, allowing it to acclimate in a clean, dry area (up to 24 hours if needed). For faster

relaxation in cold environments, gently warm with a heat gun and apply weights. - Tools Needed:

Straight edge, connector clips, floor hooks, tape, utility knife, cold weld paste, weights, and instructions. - Measure & Cut:

Use a utility knife to trim the mat to size if needed. This matting is easy to cut in order to suit specific spaces. - Lay in Place:

PVCAir mats are designed for loose-lay installation. Lay the mats side-by-side for larger areas, ensuring they sit flush. - Connect with Clips or Joining Strips:

Use connector clips at regular intervals to secure mats together. If using joining strips, apply cold weld paste and weights, allowing 30 minutes for each side to dry. Repeat on both sides for a seamless finish. - Add Edge Trim (Optional):

For a modular mat, use PVC edging to fit around the mat. Mitre the edges at 45° for corners and apply cold weld paste. Hold with weights and allow 30 minutes to set before continuing around all sides. For durability, let the entire installation set for 24 hours.

This easy-to-follow guide ensures a secure, professional installation, enhancing workplace safety with PVCAir’s high-traction and anti-fatigue benefits.

Cleaning Instructions:

Maintaining a regular cleaning schedule will help maximise the effectiveness and longevity of your PVCAir matting.

Preparation

- Begin by brushing or vacuuming the mat to remove loose debris.

- Scrape any solid deposits from the surface, and use a chewing gum remover if necessary.

Hand Cleaning

- Spray a suitable cleaning fluid over the matting and allow it to penetrate grease or dirt.

- Use a stiff brush to work the cleaner into the surface.

- Rinse thoroughly with clean water.

Machine Cleaning

- After pre-spraying with cleaning fluid, clean the top surface by using a cylindrical brush machine, moving in the direction of the ribs.

- For mats with etched patterns where dirt may collect, make additional passes across the ribs for thorough cleaning.

Steam Cleaning

- Any type of steam cleaner can be used. Optimal results are achieved with a nozzle pressure of about 6895 kN/m² (1000 psi) and a water temperature of 100°C.

- Dilute the cleaning fluid according to the steam cleaner manufacturer’s recommendations.

- For best results, spray a hot cleaning solution onto the mat, let it sit for a few minutes, then steam it off.

Degreasing

- For greasy mats, such as those in food preparation areas, immerse the mat in a solution of warm water and a suitable cleaning fluid. Use the manufacturer’s recommended mix.

- Allow the mat to soak until grease begins lifting from the surface.

- Lightly brush the mat with a stiff bristle brush and rinse thoroughly with clean water.

Recommended Cleaning Fluids: Choose a liquid cleaning fluid over powder to prevent residue build-up. Avoid powders that may leave a film on the matting surface.

Ancillaries

PVC Edging (W: 60mm X H: 14mm)

Supplied in rolls of 10.1m length. One tube of cold welding paste recommended for every 10m of edging. Comes in black, dark grey, dark brown, holly green, Oxford blue and yellow. Size: 60mm x 14mm x 10.1m.

Aluminium Edging (W: 45mm X H: 14mm)

Supplied in sections of 2m length with fixing screws and plugs. Comes in anodised aluminium and powder coated yellow. Size: 45mm x 14mm x 2m.

Large Floor Hooks (H: 14mm)

For securing sections of matting to the floor. Supplied in packs of 10 with screws and plugs.

Connector Clips: Side-to-End (H: 14mm)

For joining sections of matting together side-to-end. Supplied in packs of 10.

PVC Edging (W: 100mm X H: 14mm)

Supplied in rolls of 10.1m length. One tube of cold welding paste recommended for every 10m of edging. Comes in black, dark grey and yellow. Size: 100mm x 14mm x 10.1m.

Small Floor Hook (H: 14mm)

For securing sections of the matting to the floor. Supplied in packs of 20 with screws and plugs.

PVC Snap Track (H: 14mm)

Two-part snap track that can be welded together to join rolls end-to-end or side-to-side to cover large areas. We recommend one tube of cold welding paste for every 10m of edging. Comes in black and dark grey. Size: 14mm x 2.5m.

Connector Clips: Dual Purpose (H: 14mm)

For joining sections of matting together side-to-side or end-to-end. Supplied in packs of 10.

Specifications

| Application: | Workshop flooring, factory safety matting or multipurpose workplace matting |

| Product: | PVCAir Workplace Matting |

| Colour: | Black |

| Material: | Flexible Polyvinyl Chloride (PVC) |

Potential Applications

- Walkways in wet & dry environments

- Production & assembly lines

- Workstations

- Roof walkways

- Marine docks & quays

- Boot & van lining

- Entrance matting

Technical Data

| Properties | Value | ||

|---|---|---|---|

| Thickness | 10mm | ||

| Standard Roll Options | 10 x 0.5m | ||

| 10 x 0.75m | |||

| 10 x 1m | |||

| Weight | 4.5kg/m2 |