Comfort Link Connectable Cushion Matting

Key Features

- Durable natural rubber and nitrile construction

- Quick and easy connection system

- Excellent anti-fatigue properties

- Anti-slip texture surface

- Good resistance to UV and ozone deterioration

- Anti-trip edging available

Product Description

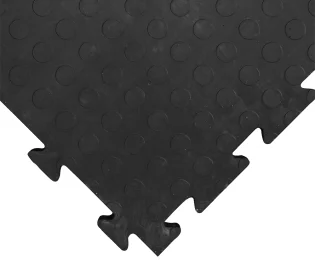

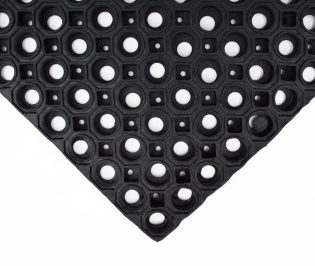

Our Comfort Link connectable cushion matting is a highly versatile flooring solution designed to improve workplace comfort, safety, and efficiency. Built from durable rubber compounds, this modular matting system combines outstanding anti-fatigue properties with excellent slip resistance, making it ideal for a wide range of industrial and commercial environments.

The top surface of our matting features a low-profile texture design. This enables them to provide good levels of grip for all footwear types, in both dry and wet conditions. The top surface also features multi-directional drainage channels to help carry liquid away from the surface of the matting. The underside of the matting features a series of gripping nibs. These help to grip a variety of surfaces without the need for bonding or permanent fixing.

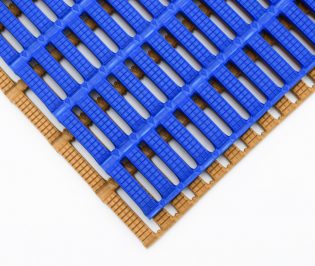

Supplied in 91cm x 91cm mats as standard, each mat features male and female connectors around the outer perimeter for easy coverage of large areas. To improve safety and usability we can supply ramped edging, which easily connects to the matting for a secure fit. We can also produce the matting and edging in Black, Red and Yellow to create easily identifiable walkways and workstations.

We manufacture our connectable rubber cushion matting in a variety of grades and compounds in order to suit specific requirements. This ensures that you do not pay for material properties that you do not need.

Standard – Natural Rubber & Nitrile (25%)

As the name suggests, this standard grade is suitable for a wide variety of applications as well as working environments. Our standard version matting provides limited resistance to chemicals and oils.

ESD General Purpose Grade

Our general purpose ESD grade provides superior electrical resistance in order to meet IEC61340-4-1 specification. This makes it suitable for use in a variety of electrical component and switchboard applications.

Nitrile Rubber Compound

This manufacturing compound provides our matting with superior resistance against most industrial oils and chemicals while preserving anti-fatigue properties.

Flame Retardant Nitrile Grade

Our flame retardant grade of nitrile enhances our matting with superior resistance against fire and sparks. This unique feature makes these mats perfect for use in welding applications as well as fire sensitive environments.

Flame Retardant Nitrile with Abrasive Coating

This particular grade offers the same flame retardant properties as the previous grade with additional slip resistance. The coating enables our matting in order to provide excellent levels of grip even in extremely wet environments.

Flame Retardant ESD Nitrile Grade

Our flame retardant ESD nitrile grade combines excellent fire resistance with electro static dissipative properties. This provides unbeatable safety for virtually every industrial application.

Specifications

| Application: | Anti-fatigue matting in a variety of industrial and manufacturing applications |

| Product: | Connectable Cushion Matting |

| Hardness (Shore A): | 50° - 70° |

| Material: | SBR, Nitrile |

| Colour: | Black. With Black or Yellow Edging |

Potential Applications

- Industrial environments

- Work stations

- Manufacturing plants

- Assembly lines

- Gym and leisure applications

- Heavy equipment handling

- Electrical component handling

- Garages and workshops

Technical Data

| Matting Sizes | Thickness | Specifications | Values |

|---|---|---|---|

| Standard Matting | Wear Resistance | Wear resistant surface to Level 3 | |

| 91cm x 91cm | 16mm | Anti-Fatigue | Anti-fatigue protection to Level 3 |

| All Other Grades | Slip Resistance | Slip resistance Level 3 | |

| 91cm x 91cm | 19mm | Chemical Resistance | Chemical resistant |

| Cut to Size | Mats can be cut to bespoke sizes | ||

| Dry Area | Suitable for use in dry areas | ||

| Heavy Areas | Suitable for use in heavy use areas | ||

| Oil Area | Suitable for use in oily and greasy areas | ||

| Welding Area | Suitable for use in welding areas | ||

| Wet Area | Suitable for use in wet areas |