D Fenders

Key Features

- Excellent impact absorption and shock resistance

- Long service life in marine and outdoor environments

- High resistance to UV, saltwater, weathering and ozone

- Suitable for boats, docks, jetties, quays, pontoons and buildings

- Available in solid or hollow rubber designs

- Pre-drilled options for fast, easy installation

- Can be supplied pre-curved, chamfered and cut to length

Product Description

The Rubber Company manufactures and supplies a comprehensive range of high-quality rubber D fenders designed to provide outstanding impact protection, durability and long-term performance. Our marine rubber fenders and industrial D fenders are widely used across ports, harbours, jetties, vessels, vehicles, loading bays and buildings where reliable protection is required.

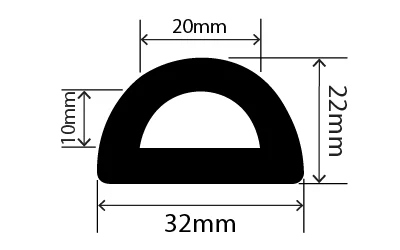

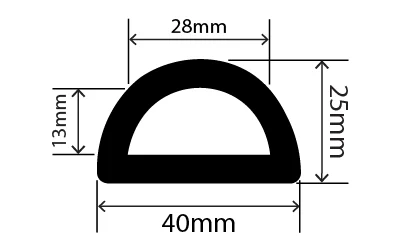

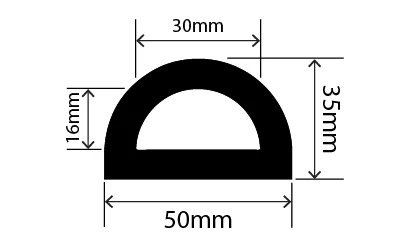

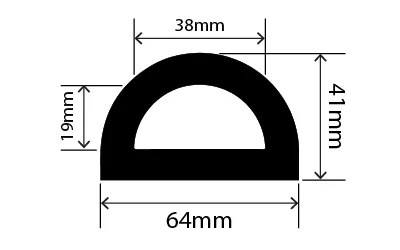

Available in solid or hollow profiles and produced in sizes from 20mm to 500mm, our rubber D section fenders can be tailored precisely to suit your application.

What are D Fenders?

Rubber D fenders are impact-absorbing protective profiles shaped like the letter “D”. They are designed to be bolted directly to flat surfaces, providing a tough and resilient barrier that absorbs collisions, vibration and abrasion.

They are commonly used as marine fenders, dock bumpers, quay protection systems and vehicle impact guards thanks to their ability to withstand heavy loads and harsh environments.

Materials & Compounds

Our extruded rubber D fenders are available in a choice of premium materials:

• EPDM Rubber – Superior UV, ozone and weathering resistance for long-term outdoor use

• Natural Rubber / SBR – Excellent resilience, impact resistance and abrasion resistance

• PVC – Available in black or white for lighter-duty and cosmetic applications

• Non-marking TPE – Ideal for sensitive surfaces and coloured installations.

All compounds provide high tensile strength and excellent elasticity, ensuring your fenders do not warp, crack or deteriorate under repeated impact.

Custom Manufacturing & Finishing

We offer a fully bespoke service to ensure you receive the perfect rubber marine fender:

• Pre-drilled bolt holes for accurate fixing

• Custom lengths

• Pre-curved profiles for hulls and rounded surfaces

• Chamfered ends for neat, professional installation

This means your D fenders arrive ready to install, reducing downtime and fitting costs.

Types of Rubber D Fenders Profiles

We supply a wide selection of rubber D fender types, each designed for specific applications.

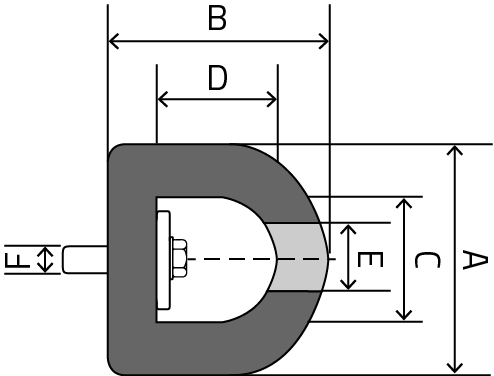

DD Fenders

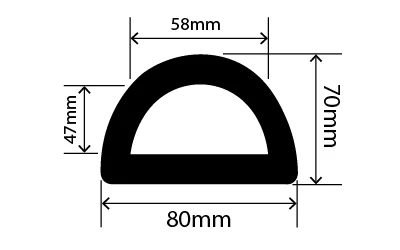

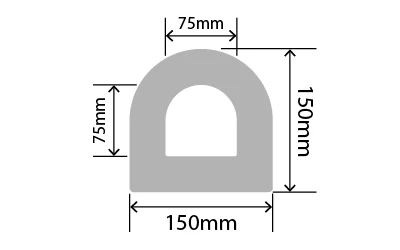

A D-shaped outer profile with a D-shaped internal bore. These are the most common marine D fenders, widely used on jetties, docks and quays.

They are drilled through the centre for secure bolt-down installation.

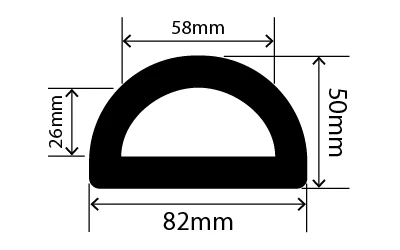

DO Fenders

Similar to DD profiles but with a round internal bore. These are drilled through the base, allowing them to be mounted into channels on vessels, making them ideal as boat and ship fenders.

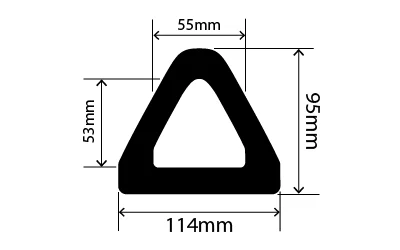

Delta Fenders

More angular than traditional D fenders, reducing the contact surface area for controlled impact absorption. Perfect for vessels, docks and marine structures requiring compact, high-performance protection.

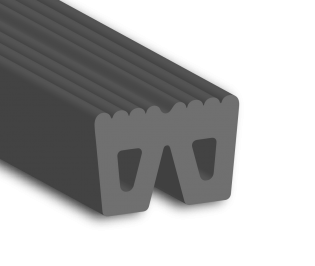

Double D (B Fenders)

Also known as rubber B fenders, these offer exceptional strength and energy absorption. Supplied with a stainless-steel fixing strip, they are quick to install and extremely secure.

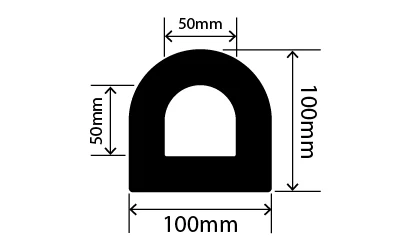

Winged D Fenders

Featuring flat mounting wings, winged D fenders provide greater stability and superior impact absorption. Commonly used on small ports, piers and vessel hulls, they are ideal for vessels that berth at unusual angles.

Available in solid or hollow (O-core) designs for different energy-absorption requirements.

M Series Fenders

Designed for continuous mounting on quays, jetties, pontoons and tugboats. They are also widely used as belting on workboats and heavy-duty marine vessels.

Solid D Fenders

Solid rubber profiles provide maximum strength and durability. While offering less compression than hollow designs, they are ideal for high-load and heavy-impact applications, such as large ships and commercial docks.

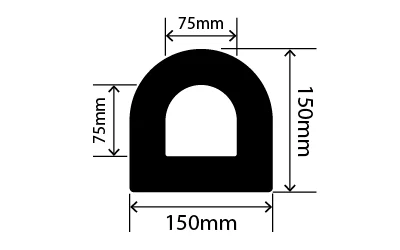

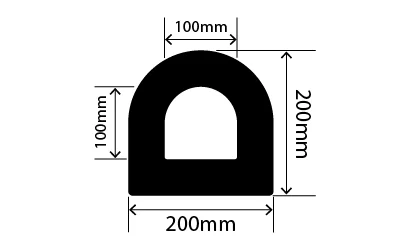

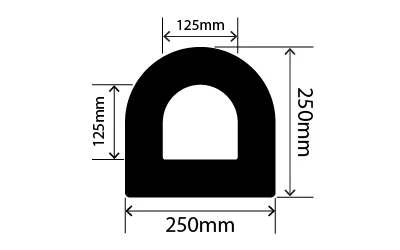

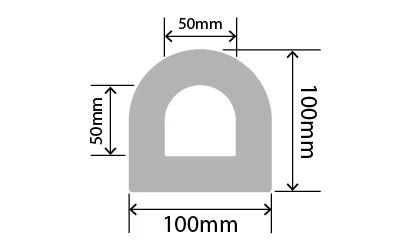

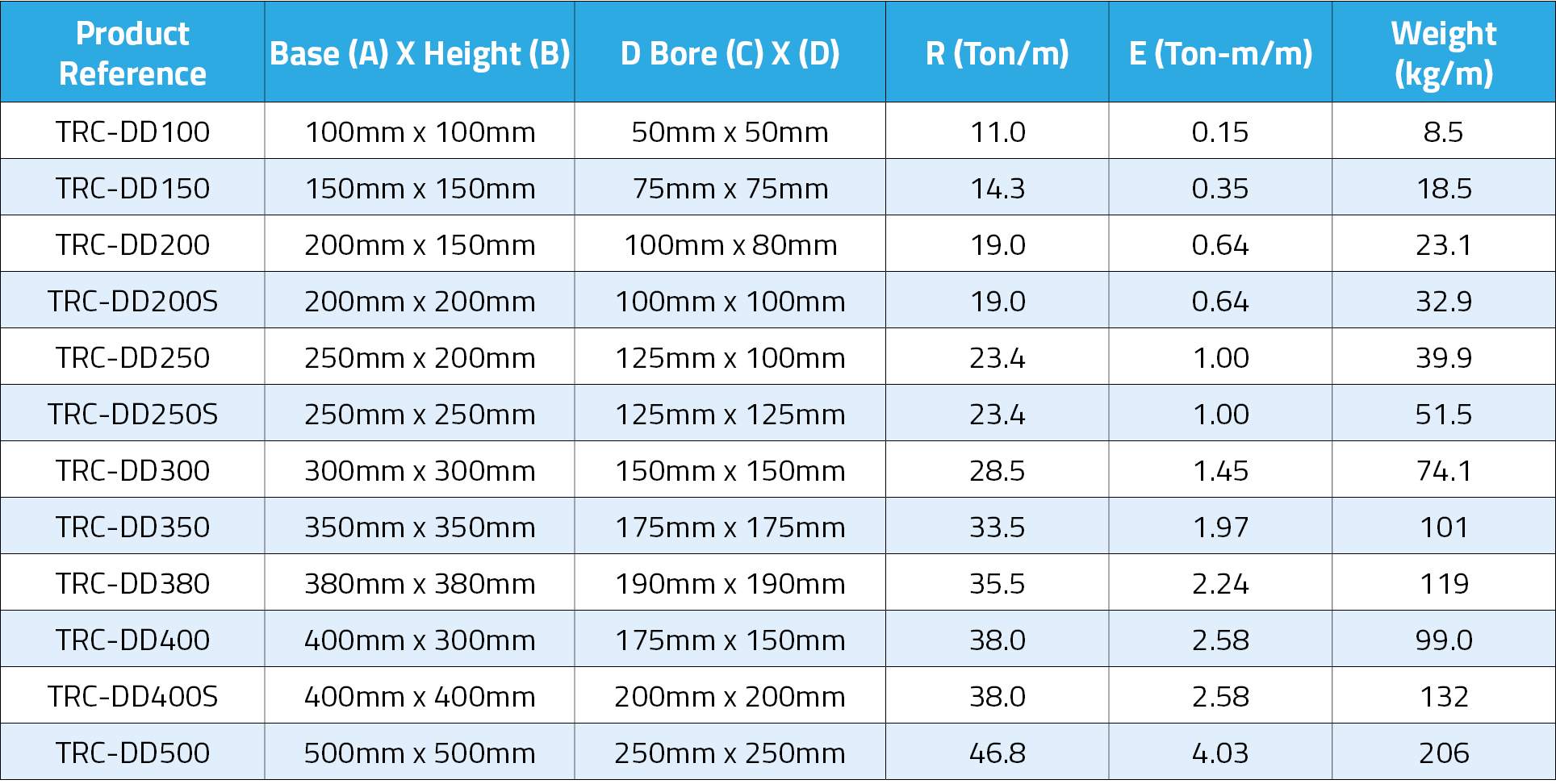

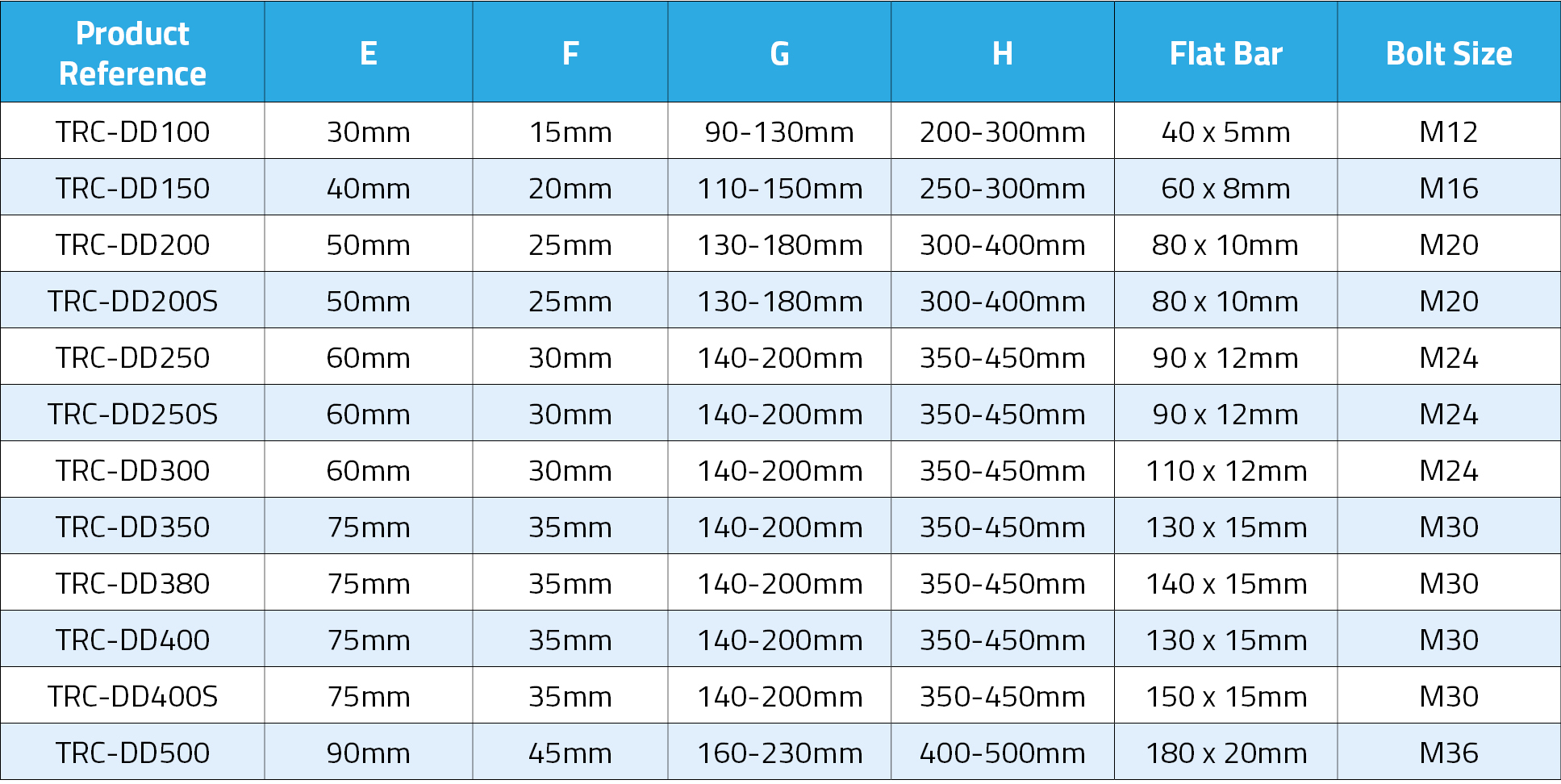

DD Fender Specifications

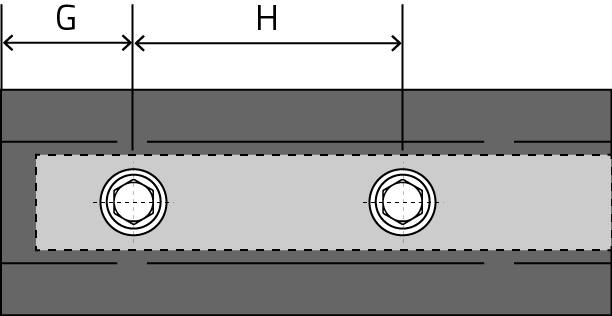

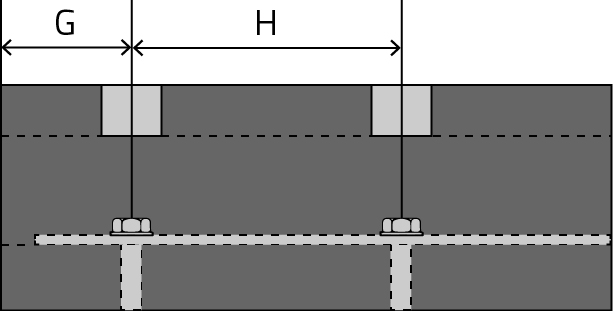

Drilling Holes and Installation

Specifications

| Application: | Impact protection in a variety of marine applications |

| Product: | Marine D Fenders |

| Hardness (Shore A): | 70° |

| Material: | Natural Rubber / SBR or EPDM |

| Colour: | Black / Non-Marking Grey |

Potential Applications

- Ports, harbours and docks

- Jetties, pontoons and quays

- Tugboats, ships and workboats

- Vans, lorries and loading bays

- Ambulances and emergency vehicles

- Factory walls and impact zones

- Shopfitting and warehouse protection

Every product is produced to deliver maximum impact protection, longevity and performance in the most demanding environments. If you need rubber marine fenders, dock bumpers or D section rubber profiles, we can manufacture them to your exact specification.