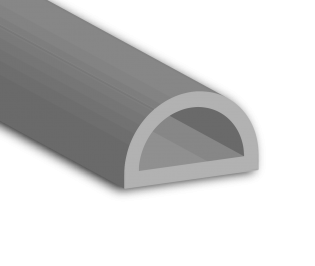

Custom Rubber Extrusions

Key Features

- Wide range of rubber compounds available

- Bespoke manufacturing to your exact requirements

- High-quality compounds

- Suitable for a variety of applications and industries

- RAL colour matching available

- FDA approved and specialised grades available

- Solid rubber, sponge rubber, and composite materials

- Variety of shore hardnesses available

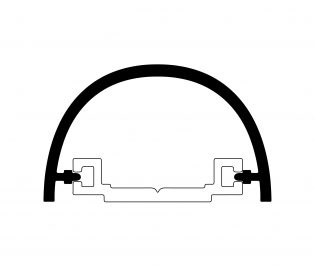

Product Description

Here at The Rubber Company, we manufacture custom rubber extrusions from a wide variety of compounds, grades and specifications. We can work directly with you throughout the design and manufacturing process to ensure that you always get an extrusion that is tailored to your unique application.

With over 100 years experience in the rubber industry, we regularly work with customers from all around the world. This experience enables us to create the most suitable and the best quality extrusion.

Manufacturing Capabilities

We utilise a unique combination of manufacturing practices and technology when creating our custom rubber extrusions. This gives you almost limitless freedom when it comes to the look, feel, mechanical properties as well as resistance of your profile.

We will always offer the highest quality solutions possible. However, we are also able to work within your specific budget and schedule for the project. Some of our key manufacturing capabilities include:

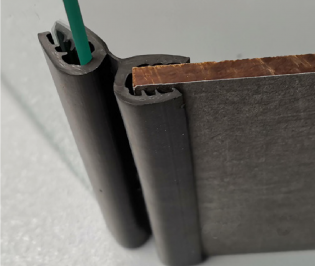

Fabrication and Joining

For secure joins, we use a range of rubber-to-rubber welding solutions. This enables us to join multiple extrusions together, either to create a watertight seal, or to fit around a specific bend radius. Unlike adhesive joining, a rubber weld fuses the two sections together in order to reduce weak points in the join. Rubber welding is often much more cost and time-efficient than creating a profile mould.

Manufacturing to Material Standards

Many applications will not require any specific material grades so a standard-use compound will suffice. However, for special-use applications and working environments, The Rubber Company has you covered. We can manufacture our custom rubber extrusions from a range of highly-specialised material standards and grades. This could be anything from Flame Retardant (EN45545-2), to FDA approved or Anti-Static grades, to name but a few. Not only does this ensure that your extrusion is made to last, but it also ensures that the extrusion will conform to health and safety regulations.

Material Compound Flexibility

Aside from solid rubber, we can also manufacture rubber extrusions from sponge rubber, as well as composite materials. Depending on your application, a solid rubber extrusion may be too hard and not flexible enough. We offer a wide selection of sponge rubber profiles, as well as bespoke sponge manufacturing. We can also provide composite extrusions which are typically manufactured from two or more different materials. We can work directly with material compounders to find a material that perfectly suits your application.

RAL Colour Matching

Although rubber is typically black in colour, we have the ability to offer RAL colour matching using certain compounds. This enables our custom rubber extrusions to perfectly fit your application or branding. It can also be useful for adding higher visibility or hazard warning to objects. Using certain compounds, such as TPE, we can also produce non-marking rubber. This is typically popular for customer facing applications, such as yachts and commercial applications.

Popular Material Compounds

There are many different rubber compounds available for use when manufacturing extrusions. It is crucial to select the right compound to match your application as each compound offers slightly different properties. This not only ensures that your extrusion will be fit for purpose, but also helps to extend the service life. Below is a list of some of the most popular extrusion compounds along with the differences between them:

EPDM

EPDM is perhaps one of the most common extrusion compounds available, largely due to two key features. EPDM profiles are generally more cost-efficient to extrude when compared to more specialised materials and grades. EPDM is also a highly versatile material, offering good mechanical properties and good resistance to weathering deterioration.

Silicone

Silicone is another popular extrusion material due to the good resistance it offers against a wide variety of common chemicals. We can produce silicone extrusions in a wide variety of colours, and are often able to match specific RAL colours. It provides excellent high temperature resistance and is also available FDA approved.

Neoprene

Neoprene features excellent resistance against oil and fuel deterioration. It also offers many of the same weathering resistance properties found in EPDM, but with superior abrasion and tear resistance. These properties often make neoprene the first choice for use in automotive applications.

TPE

Despite being lesser known than the materials mentioned above, TPE is an incredibly versatile extrusion material. It provides a middle ground between rubber and plastic materials. TPE is non-marking, which makes it ideal for use in high-end or customer-facing seals. It is also available in FDA approved grades and offers good weathering and chemical resistance.

We can also manufacture custom rubber extrusions from Natural Rubber, SBR, Butyl, Nitrile, Viton, Polyurethane, Hypalon, Epichlorhydrin, and Fluorosilicone. Please contact us for more information regarding our full range of rubber extrusion compounds.

Finishing Options

We understand that profile finishing is crucial and so we offer different finishing solutions for our custom rubber extrusions. These can vary from pre- and post-production techniques, which we tailor to each unique manufacturing run. This enables us to ensure that you always get the best profile or seal possible.

Mirror Welding

We utilise mirror welding on profiles that we produce in frames, corners, and rings. It enables us to produce these shapes without the need for adhesive and additional material. The profiles are able to maintain their flexibility, with no significant hard or weak point. It also provides a far superior sealing property than any bonding would be able to achieve.

Automatic Cutting

Our automatic cutting machines enable us to produce very short (as low as 10mm) and specific cuts. Our cutting tolerances are L2 as standard (L1 upon request).

Miter Cutting

We can miter cut our profiles to a wide range of angles. This enables our profiles to seal around corners without distorting and warping. It also ensures that our profiles are able to provide consistent protection where required. We can also add closed ends to fenders and other hollow profiles.

Inkjet Marking

We have the ability to print simple logos, names, and product references directly onto our profiles. This can be particularly useful for promotional or branding purposes, or to mark different profile and production batches. The printing process is designed to remain in place, even during use, for many years.

Drilling and Punching

Post-production, we can add holes of virtually size using different drilling and punching tools. We can position and space the holes to your exact specifications in order to ensure a secure fit. We can even drill holes of different sizes to enable you to use fixing tools.

Sliding Additive

We can supply our profiles with a spray-on sliding agent on either specific parts, or the entire profile. This aids in installation, particularly on parts with a low tolerance or high friction. The sliding solution we use is silicone-free.

Anti-Stretch Wire

During the extrusion process, we can insert an anti-elongation wire within the profile itself. This helps to ensure that the profile is able to maintain its form while under pressure.

Self-Adhesive Backing

We can supply our profiles with a number of different adhesion solutions depending on the specific application. This can include a high-quality, easy-peel adhesive backing layer for quick installation. We can also supply different adhesives to create a secure bond between the profile and a number of different materials.

Specifications

| Application: | Sealing, protection, and fluid transfer for a variety of industries |

| Product: | Custom Rubber Extrusions |

| Hardness (Shore A): | Please enquire regarding material hardness |

| Material: | Please enquire regarding available compounds |

| Colour: | Black (as standard) |

For Enquiries, Please Include:

- 1) Application, temperature range, internal/external use

- 2) Sample or drawing

- 3) Colour required – sample, RAL, Pantone, or BS

- 4) Material required, if known

- 5) Quantity required – both samples & bulk order annual usage

- 6) Coil or cut lengths