Expansion Seals & Joint Fillers

Key Features

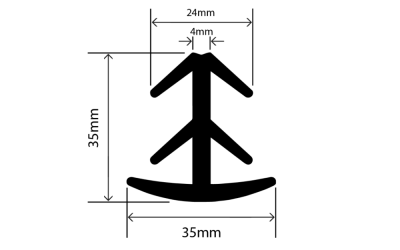

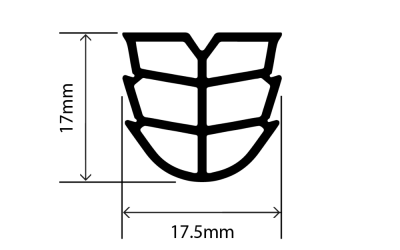

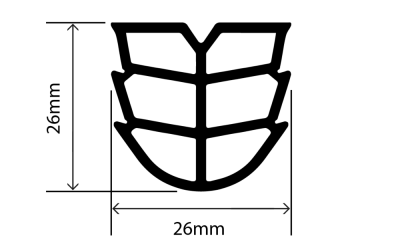

- Wide selection of profiles available

- Lightweight with high strength

- Good abrasion resistance

- High impact resistance

- Wide functioning temperature range

- Superior life expectancy

- Good ozone and weathering resistance

- Fast and simple installation

- Minimal maintenance required

Product Description

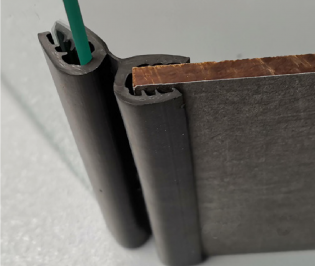

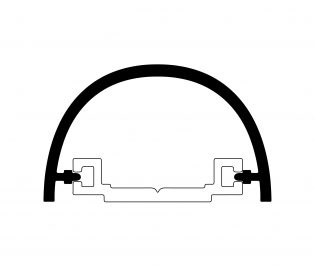

Expansion seals or expansion joints as they are also known, provide a subtle yet crucial function in a wide variety of construction applications. The key purpose of an expansion seal is to provide a flexible connection point between two concrete, cement or similar structures. We specifically manufacture our TPE expansion seal profiles to provide excellent abrasion as well as impact resistance. This enables our expansion seals to provide a superior life expectancy compared to similar alternatives.

You can view our standard range of expansion seal profiles on our PDF which is attached to this page. We can also manufacture bespoke profiles to your exact requirements, subject to minimum order quantities and a tooling charge.

Once installed, our TPE expansion seal profiles create a bridge which absorbs the energy created from the two structures moving. This aids structures to efficiently cope with the extreme rates of compression caused by everyday use and adverse weather. Aside from absorbing compression our expansion seal profiles can also create a waterproof seal between two structures. This makes our product ideal for use in bridges and other applications where water and debris can build up.

Specifications

| Application: | Large & small scale bridges, parking garages, tunnels, large buildings, heavy load applications |

| Product: | Expansion Seal / Expansion Joints |

| Hardness (Shore A): | 60° - 72° |

| Material: | TPE |

| Colour: | Black |

Potential Applications

- Car parking garages

- Large and small scale bridges

- Heavy concrete walls

- Roofing

- Heavy duty traffic

- High load applications

- Tunnel construction

- Water treatment plants

Technical Data

| Properties | Test Standard | Values | |

|---|---|---|---|

| Compound | - | Thermoplastic Elastomer (TPE) | |

| Density | ASTM D792 - ISO 1183 | 0.97 kg/m3 | |

| Tear Resistance | ASTM D412 - ISO 37 | 7.4 Mpa | |

| Elongation at Break | ASTM D412 - ISO 37 | 450% | |

| Minimum Temperature | - | -50°C | |

| Maximum Temperature | - | +90°C | |

| Compression Set (22hrs @ 125°C) | ASTM D395 B - ISO 815 | 30% | |

| Compression Set (70hrs @ 125°C) | ASTM D395 B - ISO 815 | 41% |