Food Quality Gaskets

Key Features

- High quality material

- Bespoke manufacturing service

- Safe for food & beverage contact

- Confirms to FDA manufacturing standards

- Wide operating temperature range

- Solid & sponge rubber materials

- Wide variety of rubber compounds available

- Wide range of thicknesses & hardness’s

Product Description

We can bespoke manufacture food quality gaskets from a wide variety of solid as well as sponge rubber compounds. Our food contact gaskets fully conform to FDA standards for use in food and beverage applications. Our dedicated team can work directly with you, giving you expert guidance every step of the way. This ensures that you can always get the best gaskets possible in order to suit your unique requirements.

Many of our food quality gaskets offer a wide operating temperature as standard. While the maximum temperature can vary from material to material, the compounds have been designed for consistent high temperature use. Aside from being non-toxic and non-allergenic, our food contact gaskets also provide great mould and water resistance. This helps to prevent organic matter from forming on the surface of the material. Food grade rubber gaskets are also tasteless and odourless, which ensures that the quality of the food and beverage is not affected.

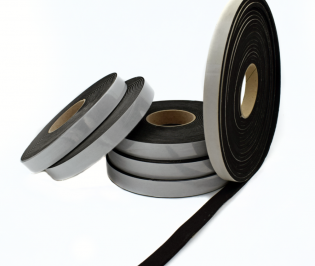

We typically manufacture our food quality gaskets from sheets or rolls of rubber. This enables us to produce uniform, large format gaskets without the need for bonding or joins. We also have a diverse range of cutting and manufacturing machinery available. This allows us to produce simple as well as complex gaskets with tight tolerances. The cutting method can change depending on the thickness of the material, quantity required as well as complexity of the gaskets.

Popular Compounds

There are many food quality rubber compounds available, which each material offering slightly different properties. It always important to select the correct material to suit your application. This ensures that your gaskets are suitable for use, but also that you don’t pay for properties that the application does not require. We have included a list below of our most popular food contact gasket materials.

EPDM Rubber

Aside from being food contact safe, our EPDM food grade gaskets also provide excellent weathering and ozone resistance. This enables them to function in both interior and exterior applications without affecting the service life of the material. For applications that require it, EPDM gaskets also feature good ageing and chemical resistance.

Neoprene Rubber

Neoprene food contact gaskets combine food safe properties with good resistance against oils, fats as well as grease deterioration. This enables them to be used in a number of highly specialised applications. Neoprene typically offers impression mechanical properties such as; high tensile strength and tear resistance properties. This enables the gaskets to provide consistent performance, even in frequent use applications.

Silicone Rubber

Silicone rubber is perhaps the most common material for manufacturing food contact gaskets. These gaskets combine good chemical resistance with the excellent high temperature resistance. Silicone rubber also features good mechanical properties as well as good resistance against weathering, UV and ozone deterioration. This ensures that our food grade silicone gaskets are suitable for a wide variety of applications and environments.

Natural Rubber

Natural rubber gaskets are well known for offering superior flexibility and elongation properties when compared with other rubber compounds. They can also provide high tensile strength, tear and abrasion resistance. This combination of physical properties makes natural rubber food grade gaskets suitable for use in high wear and compression applications. Natural rubber gaskets also feature good resistance against alcohol, ketones and organic acids deterioration.

Nitrile Rubber

Our nitrile food grade gaskets are available in either blue or white colours depending on the application. This is a premium quality material, which is manufactured to provide a high service life in abrasive applications. It features good oil, fat and grease resistance as standard as well as wide operating temperature range.

For more detailed information on each material we suggest visiting the solid and sponge sheeting sections of our website. Here you can view standard thicknesses, as well as download material datasheets. Click here view our solid rubber sheeting materials, and click here view our sponge rubber sheeting materials.