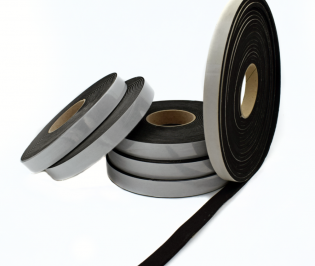

Gland Packing

Key Features

- Highly durable materials

- Good wear & tear resistance

- Helps to increase machine service life

- Reduces machinery downtime

- Simple & easy to install

- A single roll can be used across multiple machines

Product Description

Our gland packing seals provide a simple and cost efficient solution in order to reduce machinery wear and maintenance. Our standard range includes; GRAPHITE, PTFE and GREASY. These materials have been specifically chosen for their excellent wear resistance as well as fluid sealing properties. They can also provide good chemical resistance and tolerate poor mechanical conditions, with off-centre shafts or worn bearings. Our gland seals meet requirements for potable water, food as well as fire safe valve applications, getting fugitive emission control – often to below 50ppm.

Aside from the gland packing materials themselves we also offer associated products that have been designed to work with the seals. Popular products include: packing ring cutter, pre-formed packing rings, precision moulded to fit each gland, copper anti seize compound, graphite grease, molyon grease, nickel anti seize compound, silicone grease and packing extractors. These products help to increase the functionality as well as service life of the gland seals.

Some of our most popular gland packing seals include: tank lid furnaces & crucible lids, pumps/rams, centrifugal pumps/rotary, plant reciprocating pumps/rams. We offer a wide range of gland seals that can suit virtually every application in a variety of industries.

Technical Data

| Sizes | Lengths | ||

|---|---|---|---|

| 3mm to 25mm | 8 metres per box |