How to Measure a Gasket

We have designed this guide to show you how to measure a gasket. This will ensure that we can produce a gasket to your exact specifications without any confusion. As there are many different types of gaskets and different terminology it can be confusing. We have taken two of our more commonly requested gaskets below and detailed how to provide all of the required dimensions.

Flange Type Gaskets

Flange gaskets are generally the most common type of gasket and the one that most people will generally think of. The are almost always circular in shape and are available with or without bolt holes depending on the requirement.

Measuring the Inner and Outer Diameters

Perhaps two of the most crucial dimensions for a flange gasket. The inner (ID) and out (OD) diameters ensure that the gasket will fit correctly in your application. The best way to get these measurements is to use either a tape measure or a ruler. Simply place the measuring tool edge to edge over the gasket face and note the measurements accordingly.

Measuring the Pitch Circle Diameter

As many flange gaskets also feature bolt holes it is important to accurately measure the gap between opposite holes. Depending on the size of the gasket the best measuring tool to use is a digital calliper as this will give the most accurate reading. You can also use a tape measure or ruler however. To calculate the pitch circle diameter you need to measure from the inside of one hole to the inside of the opposite hole. Please note, this method only works assuming both hole diameters are equal.

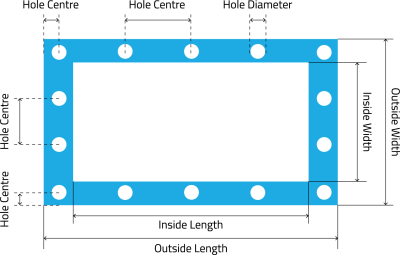

Picture Frame Type Gaskets

These particular type of gaskets are typically square or rectangular in shape. Much like flange gaskets, picture frame gaskets will also require both outside and inside measurements. These can be slightly more complicated for rectangular gaskets as multiple measurements are required, however the measuring process remains the same. Picture frame gaskets will often feature bolt holes around the frame with a consistent diameter and spacing. It is always worth checking however as this may not always be the case.

Other Considerations

Aside from the measurements stated above it is always important to measure the thickness of the gasket. This will ensure that you are able to achieve the best fit and seal. Do not hesitate to get in contact with us if you require any assistance with measuring your gasket. Our friendly and helpful team are always on hand to guide you through the process.

Common Materials

- Butyl

- EPDM

- Natural Rubber

- Neoprene

- Nitrile

- Novus

- Silicone

- Sponge rubber

- Tico

- Viton

Potential Industries

- Aerospace

- Automotive

- Construction

- Electrical

- Energy generation

- Food & beverage

- Marine

- Pharmaceutical

- Oil & gas

- Transportation