Polyethylene Foam Material

Key Features

- Highly durable material

- Good chemical & grease resistance

- Water resistant

- Impervious to mildew, rot & bacteria

- Good UZ, Ozone & weathering resistance

- Lightweight and flexible

- Wide functioning temperature range

- Easy to cut & shape

Product Description

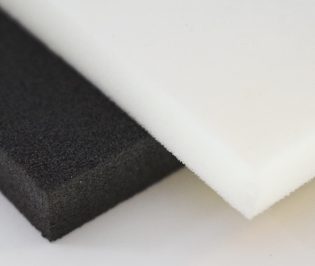

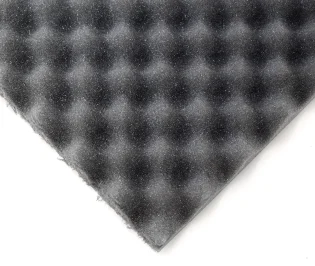

The Rubber Company supply and manufacture polyethylene in a variety of colours and formats. Polyethylene is a closed cell foam, also referred to as a PE foam or LDPE foam. The material starts off as a thermoplastic which is then blown into a foam format. This is a highly durable as well as versatile product.

The high compression rates that polyethylene offers enable it to maintain its resilience under repeated impact. It also gives the material excellent load bearing characteristics. The incredible versatility of this product enables you to use it in almost all applications. However, our customers often use it as; packaging, case inserts, flotation, flooring and acoustic underlay, camping mats to name but a few. The soft nature of the material makes it particularly useful in packaging applications as it is able to absorb impacts without damaging the contents of the package.

The Rubber Companies production facilities are able to convert polyethylene into a variety of formats to suit your specific requirements. We commonly get requests for polyethylene in: sheets, rolls, strips, gaskets as well as seals. We can also produce this material either plain or adhesive backed for easy installation. The polyethylene we offer is available in four densities, 18, 24, 33 and 45kg/m3. Each density has its own values so be sure to check our material spec sheet in order to ensure you get the right density for your specific requirements.

We offer a range of polyethylene foam products including gaskets, cut strips, full-length rolls, knee pads, and case inserts. Please contact us to see how we can meet your requirements.

Specifications

| Application: | Shock absorption, thermal insulation, acoustic sound proofing |

| Product: | Polyethylene Foam Sheeting |

| Hardness (00): | 50° - 60° |

| Material: | Polyethylene |

| Colour: | Black, White, Blue, Red, Yellow, Green available as standard. Other colours available as a special order. |

Potential Applications

- Shock absorption

- Packaging protection

- Case inserts

- Buoyancy aids

- Thermal insulation

- Kneeling pads

- Acoustic sound proofing

- Camping mats

Material Conversion Possibilities

Here at The Rubber Company we can utilise a variety of sponge rubber conversion tools and techniques. This enables us to cut, shape, drill, join and laminate our materials to match your exact requirements. Rubber sponge materials are manufactured in large blocks, so it is necessary to convert these blocks into usable end products. Our dedicated team can work directly with you every step of the way. This ensures that we use the best methods in order to achieve your desired shape and finish.

Technical Data

| Properties | Values 18 kg/m3 | Values 24 kg/m3 | Values 33 kg/m3 |

|---|---|---|---|

| Hardness (Shore OO) | 50° | 50° | 60° |

| Cell Size | 0.3mm | 0.3mm | 0.37mm |

| Tensile Strength | 300 kPa | 320 kPa | 440 kPa |

| Elongation at Break | 125% | 130% | 155% |

| Tear Resistance | 520 N/m | 495 N/m | 785 N/m |

| Compression Set (25%, 1/2hr) | 13% | 13% | 10% |

| Compression Set (25%, 24hrs) | 5.5% | 5% | 3% |

| Compression Set (50%, 1/2hr) | 27.5% | 27% | 22.5% |

| Compression Set (50%, 24hrs) | 18.5% | 19% | 13.5% |

| Compression (10%) | 33 kPa | 34 kPa | 51 kPa |

| Compression (25%) | 50 kPa | 53 kPa | 69 kPa |

| Compression (40%) | 81 kPa | 85 kPa | 102 kPa |

| Compression (50%) | 113 kPa | 118 kPa | 137 kPa |

| Thermal Conductivity (10°C) | 0.0446 W/m.K | 0.0392 W/m.K | 0.0405 W/m.K |

| Flammability (FMVSS302) | Pass (14mm and thicker) | Pass (12mm and thicker) | Pass (7mm and thicker) |