Cross Linked EVA Foam

Key Features

- Cross-linked material

- Good strength & recovery properties

- Excellent low temperature resistance

- Good stress-crack resistance

- Good UV resistance

- Many densities & thicknesses available

Product Description

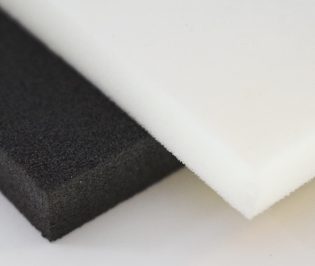

Our cross linked EVA foam, otherwise known as Ethylene Vinyl Acetate is a high quality, closed-cell material. The material is highly versatile, but is commonly used in sealing applications due to the air and watertight structure of the material. EVA foam is very similar in appearance to Polyethylene foams, however EVA foams have a far more rubbery and resilient feel. This serves to improve the recovery of the material, which makes it suitable for use in physically demanding applications.

We supply this particular material in densities ranging from 25 to 160 kg/m3 and a variety of thicknesses from 2mm to 100mm. We can also produce EVA foam in a diverse range of formats such as; full rolls, sheets, strip cut lengths and bespoke gaskets. This ensures that we can always provide the perfect material to match your exact requirements.

A key feature of our cross linked eva foam is the materials lightweight and durable characteristics. It is also odour-free and available in a selection of colours depending on the density required. These properties make it a particularly popular material for use in construction and automotive industries. At lower densities EVA foams are incredibly soft to the touch. This makes them ideal for use in leisure applications such as; back packs, body protectors, camping mats and helmet liners.

Specifications

| Application: | Air & watertight sealing in interior & exterior applications |

| Product: | Cross Linked EVA Foam |

| Hardness (OO): | |

| Material: | Ethylene Vinyl Acetate |

| Colour: | Please contact regarding specific colours |

Potential Applications

- Interior & exterior applications

- Air & watertight seals

- Protection pads in leisure applications

- Orthotics

- Arts & crafts

- Sports & stable mats

- Life jackets

- Full rolls, strip cut lengths, gaskets & adhesive tapes.

Material Conversion Possibilities

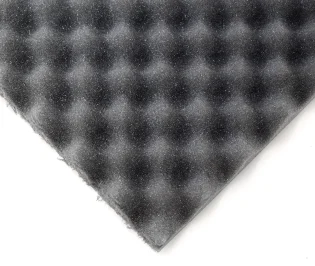

Here at The Rubber Company we can utilise a variety of sponge rubber conversion tools and techniques. This enables us to cut, shape, drill, join and laminate our materials to match your exact requirements. Rubber sponge materials are manufactured in large blocks, so it is necessary to convert these blocks into usable end products. Our dedicated team can work directly with you every step of the way. This ensures that we use the best methods in order to achieve your desired shape and finish.

Technical Data

| Properties | Values TRC06 | ||

|---|---|---|---|

| Compound | EVA | ||

| Density [Specific Gravity] | 25 - 160 Kg/m3 | ||

| Tensile Strength | |||

| Elongation at Break | |||

| Minimum Temperature | -60°C | ||

| Maximum Temperature | +80°C | ||

| Compression Set (25% 23°C for 22 hours) | |||

| Compression Set (50% 23°C for 22 hours) | |||

| Compression Deflection (25%) | |||

| Compression Deflection (50%) | |||

| Water Absorption (Max Weight Change) |